360 Capture of Work Sites

Boots on the ground in Ireland will be reduced – and ultimately eliminated - thanks to increased digitalisation.

As part of the Continuous Improvement Group (CIG) - which includes Rhomberg Sersa Ireland and their client Iarnród Éireann - Irish Rail (IÉ) - work is ongoing to upgrade the current walkout surveying process to 360 walkout surveys, known as TrackView4D.

Walkout surveys are a crucial part of examining a site to gather data prior to a track maintenance shift. The surveys are particularly important for complex sites where conditions are challenging.

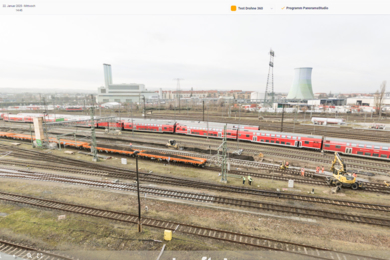

The team in Ireland – who operate and maintain the OTM fleet on behalf of Irish Rail - tested and introduced a ‘360 virtual tour’, similar to those in use in other Rhomberg Sersa markets.

These surveys involve using a camera which captures 360 views of the site, very similar to Google Streetview, but with the added benefit of being able to input and overlay critical site information into each image.

The upgrade and introduction of TrackView4D has several benefits:

- Improved safety: Reduced time on site and less boots on the ground

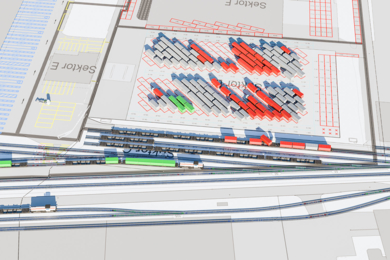

- A 3D virtual tour of the worksite: several 360-degree images at key points of the walkout

- A digital record: An interactive TrackView4D file created for review post walkout

- Embedded details: Images, voice notes, RAMS, and any other worksite related detail can be embedded into each image

- Enhance work preparation: TrackView4D files available through RSRG SharePoint for review immediately after the walkout

- Reduced environmental impact: Less site visits, less people on site and the file is viewable via RSRG SharePoint for site analysis

It is expected that the TrackView4D surveys will be of particular benefit for future working Kirow Crane shifts as they will add to the quality and safety for the lift plans for each job. For example, it will allow the team to plan exactly where to put the load, take into consideration the access and egress and allow users to review Realtime RAMS.

TrackView4D will also be used for ballast cleaning shifts and can allow a decision to be made in advance on where exactly to put the launch pit.

In advance of introducing the new surveys, a risk assessment and work instruction were drafted. Field tests were conducted to determine if any improvements could be made.

One improvement which was introduced as a result of the field tests was the introduction of powerpacks to ensure the cameras do not power down during the survey. Helmet and shoulder mounts were also added as well as a pocket clicker to activate the camera. These pieces of equipment mean that the surveyor’s hands are not occupied, and they can always keep their eyes on the track.

The virtual site tours will have a shelf life but, in the future, recordings may be made during transit shifts. This would mean data could be recorded while the machine is being moved from one position to another, ensuring efficient use of resources. It would have the added benefit of reducing boots on the ground – and therefore improving safety - as well as reducing the use of fuel.