Thinking in Connected Worlds.

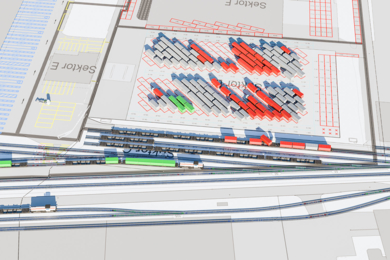

The meaningful application of mobile robotic systems on construction sites requires the integration of many disciplines.

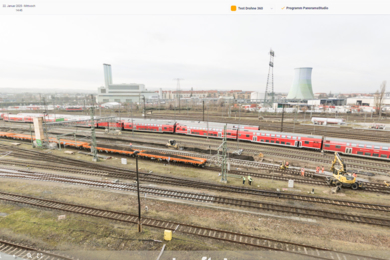

RSRG is a pioneer in the digitalisation of the railway construction industry, deploying innovative and interconnected technologies directly on-site, going beyond mere planning and documentation.

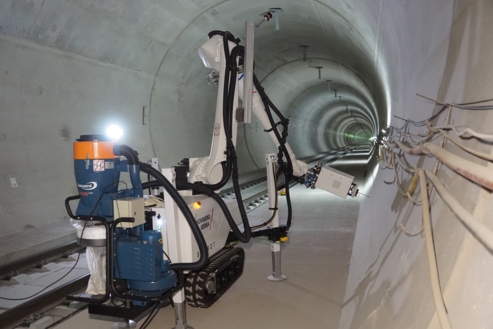

An example of this is the use of robots, which have long been indispensable in the manufacturing industry. But how do mobile robotic systems perform on construction sites where the environment is constantly changing? Initial significant insights have been gained from the deployment of a drilling robot on the Koralm Tunnel (AT) construction site.

Infrastructure projects typically use idealised standard cross-sections, which, in reality, often cannot be implemented precisely. This poses a challenge for the use of controlled machines, as an accurate digital capture of reality is required.

RSRG recognised early on that digitalising reality is a fundamental prerequisite for the successful use of robots on construction sites, and that connecting the various disciplines involved in a construction project plays a significant role. Therefore, processes were established to prepare the captured data qualitatively and make it available for further processes.

Once suitable digital models are in place, the planning specifications must then be carefully combined with the local conditions. RSRG works across team boundaries to make this process as automated and project-specific as possible. High-quality planning is crucial because it ensures that digital data is immutably translated into reality on-site, as demonstrated with the drilling robot in the Koralm Tunnel. This closes the digitalisation loop.