The Q-tainer Provides Computing Power for the “Transparent Construction Site”.

Aiming to make construction sites more efficient, safer, and more sustainable, we combine modern technologies with existing know-how in the "Transparent Construction Site" project.

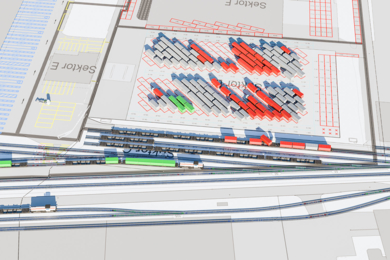

Using the innovative Q-tainer, data from the categories “Construction Site & Occupational Safety,” “Construction Logistics,” “Construction Operations,” “Machine Tracking,” and “Environment” are systematically collected and linked. Among other things, it automatically detects how many construction vehicles are in use and where, which routes they predominantly take, where there are collision risks with pedestrians, and whether safety regulations for helmets and safety vests are being followed. Additionally, through AI analysis, logistics bottlenecks and construction progress can be made transparent, allowing for quick countermeasures to delays. Continuously and automatically collecting and linking these data on-site helps close safety gaps, prevent personal injuries, reduce downtime, manage resources, and optimally distribute them among different trades on the construction site.

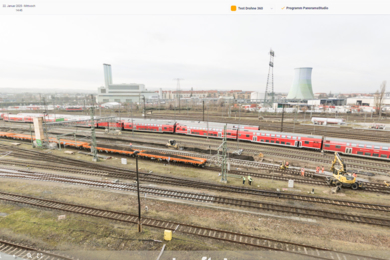

We are currently testing these new digital tools on some construction sites, focusing on various sensors and data sources. Providing these digital tools requires significant computing power, fast response times, and high data transmission bandwidth to ensure that data and derived information are available quickly and reliably. The core component of the project is the mobile data center, the Q-tainer. The Q-tainer, a platform jointly developed by RSRG and Dätwyler IT Infra, also brings a local 5G campus network to the construction site. This network wirelessly connects sensors distributed across the site. Additionally, on-site personnel can use compatible mobile devices to connect to the network for communication or digital mobile applications. This solution is available to interested customers in various configurations and packages, ranging from SaaS to traditional rental solutions.