In 2022, the SBB commissioned the ARGE SAR to develop a trackspecific positioning system for track construction machines.

As part of the digitalisation of maintenance work, SBB issued a tender for a precise positioning system for track construction machines that works both outdoors and in tunnels. In 2023, the ARGE SAR was awarded the contract for this project.

Maintenance work on infrastructure, such as tamping and rail grinding, is still documented with work reports within the SBB network. Digital, track-specific positioning of this work is not possible with this method. However, this digital information is crucial for maintenance forecasting calculations, combined with the data from the measuring vehicles.

In 2018, SBB conducted tests with initial devices on track construction machines to examine the basic feasibility of such digital work logging. In 2022, SBB publicly tendered the “mPOM” (Mobile Positioning of Maintenance Work) project.

ARGE SAR, consisting of Sersa Maschineller Gleisbau AG, ANavS GmbH, and Rhomberg Bahntechnik AG, combines expertise in the operation of track construction machines with the highly precise positioning of rail vehicles. In 2023, ARGE SAR was awarded the contract by SBB to develop the mPOM system, with the goal of deploying a total of four test systems operationally by the end of 2024.

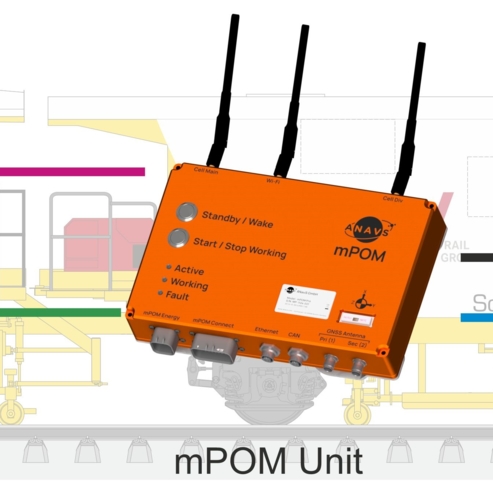

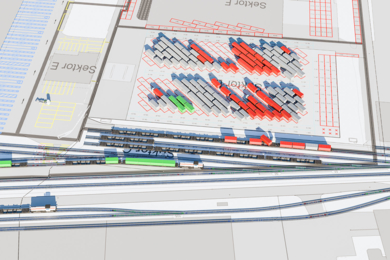

The main project requirement is the track-specific positioning of track construction machines to within ±1m in the so-called GTG network of Switzerland (track topography), both outdoors and in tunnels. The highly precise position data is determined on the track construction machines using the so-called mPOM Unit. This device from ANavS determines the GNSS position, enhances accuracy with RTK (Real-Time Kinematic), and supplements the positioning solution with an integrated IMU (Inertial Measuring Unit). Positioning in tunnels is calculated using an odometer on one of the machine's axles and the IMU.

The system's power supply comes directly from the onboard network while the machine is in operation. A modern lithium iron phosphate battery stores the energy for the period between machine deployments, ensuring the position is always known.

The data is continuously transmitted to the mPOM backend. A special algorithm improves the positioning solution, calculates the exact track position in the GTG network, and subsequently transfers the final data to SBB's SwissTamp system. Here, SBB employees can evaluate the executed work shifts along with the measuring data from the measuring vehicles.

The mPOM system will document the work of tamping machines, rail grinding, and milling machines within the SBB network. Application of the system in other networks both domestically and internationally is possible