Digitalization across the Project Life Cycle

Apart from BIM, RSRG employs a range of new technologies to offer its customers best-possible solutions in every phase of the project.

For the rail service to operate quickly, reliably and safety, it requires perfectly inter-coordinated systems: permanent civil engineering works, highly-resilient routes, energy supply, communications and command systems engineering , as well as trains designed both for transporting freight but also people at very high speed. The tasks and specialist disciplines involved in planning, construction and maintenance are diverse, and depend on the coordination of countless interfaces.

To ensure this is the case, for some time now Rhomberg Sersa has indeed looked to BIM and GIS as “Data containers for geographic and building information”.

However, a “high-performance” project needs more than BIM that is restricted to the planning phase. The model provides support to all phases of construction, and increasingly, to the maintenance aspect too. Gathering this data, in turn, helps with the optimisation of future planning and design. This is why it is important to think in project cycles and not merely in phases. RSRG acts accordingly and puts its faith in having “BIM/GIS along the Life Cycle”.

Those in charge are aware that there is some way to go before BIM is able to unfurl its full potential performance for the benefit of all stakeholders. The elaboration of the rights solutions and aptitude therefore depends not only on the development of software, but also on maintaining a focus on the people involved, so that BIM can become “business as usual” just like computers.

Field to BIM

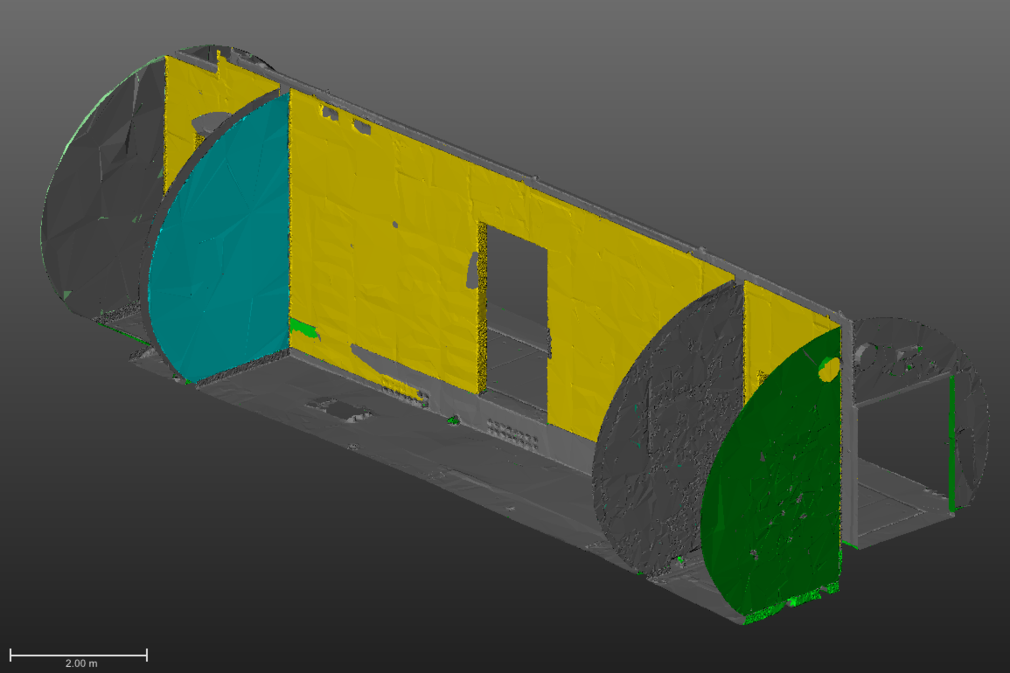

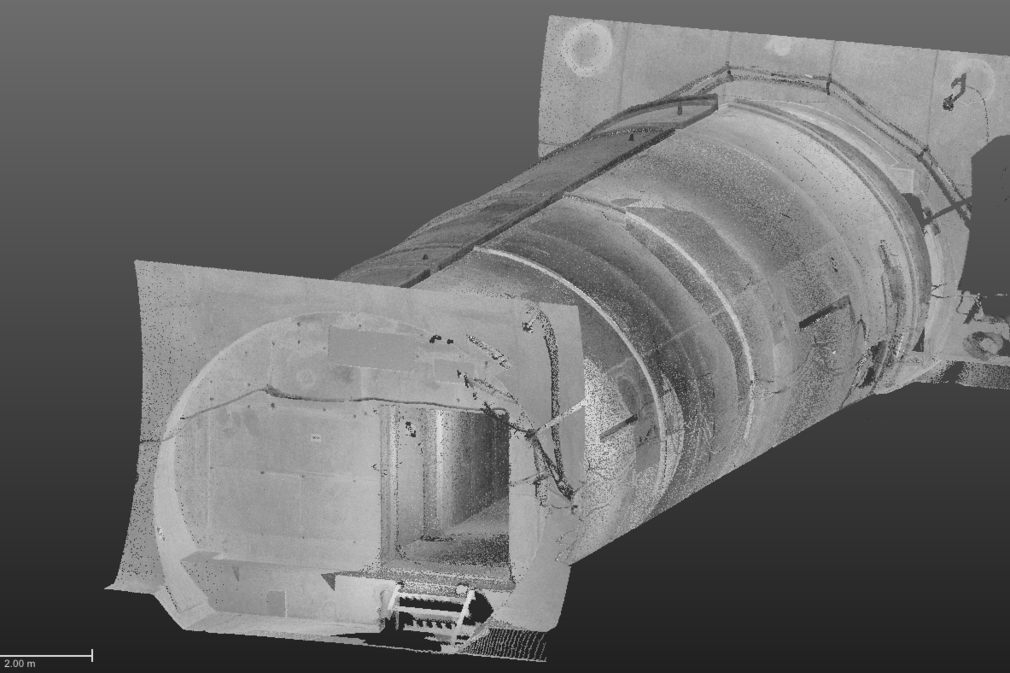

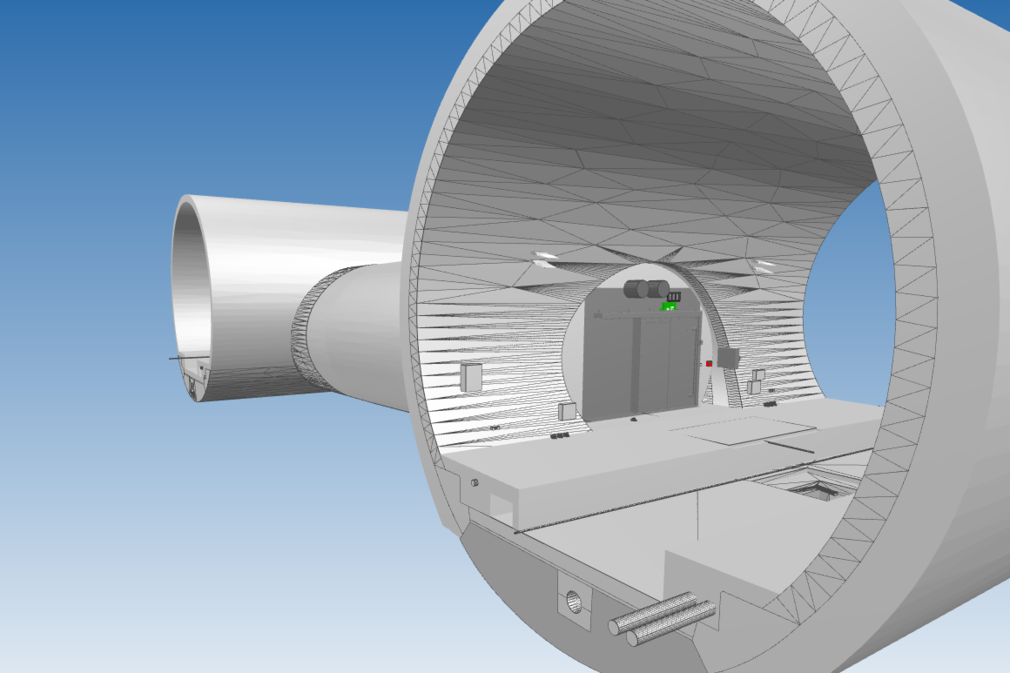

Across the entire cycle of erecting a built structure, as a construction company RSRG is tasked with planning the construction sequence, inspecting completed sections, establishing the basis for the billing, and providing the customer not only with the actual structure, but also a digital version to enable the efficient performance of the subsequent operations and maintenance works. All these tasks can be realised by digitalization tools and services provided by the Reality Capture team – such as drones, laser scanners and software – that transform the measurement data into 3D point clouds, which can precisely locate their geo-position down to the last centimetre.

During a subsequent process, these point clouds are broken down into individual, abstract objects that represent the various constructed elements. First, these objects can be tagged with additional information – variant, type, year of construction and other details – and second, they can be compared against the planned geometrical conditions (models) in order to identify any significant deviations.

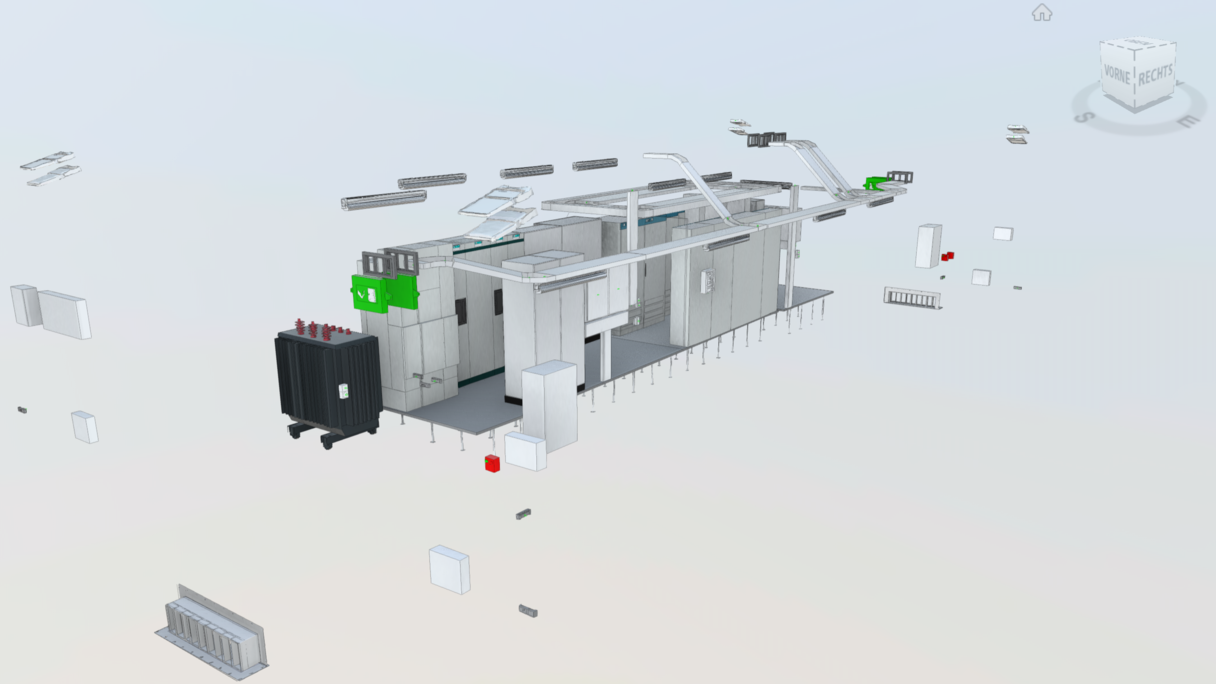

Modelling/Design

The point cloud is just one of various sources for arriving at a 3D BIM model. From a technological perspective, it is the tool of choice for transposing a reality snapshot into a virtual model, which, together with the information contained therein, assists with the relevant next step in the process. This may be a record of the status quo at the start of the project planning work, a snapshot of the construction progress of a final documentation of the executed work.

The 3D BIM model is the visible location of a project’s data model, furnished with individual objects as geometrical representations of reality. RSRG enriches these objects with data and attributes during the entire project phase, which are of relevance for the transfer of data for the subsequent processes and customers on the conclusion of the project.

The potential offered by having data consistency across the entire process takes full effect particularly in those projects where RSRG is responsible for both the planning and the execution. This potential can be brought to bear through the processes and with the aid of BIM models.

Programming and parametric works mean that at RSRG many of the modelling sub-steps are already performed automatically. Quality gates placed at neuralgic process points then examine the model for its conformity and technical content.

Information Management (CDE, Model Data Management)

All the information that is to be created, adapted, provided or achieved during the project phases, will be organised within a central database. All objects in this data model have their geometrical exponents in RSRG’s BIM model. By employing model data management, the entire documentation can be organised on a building element basis, and the object-based data made accessible to the processes and systems as per the relevant phase. The project CDE (Common Data Environment) provide the models and their information to all project members, where they can be further enriched.

GIS

Geographical information systems (GIS) are tools that allow users to access data belonging to objects displayed on maps. This enables the user to see both the location of these objects, as well as the characteristics in which these objects are stored.

RSRG employs GIS during the construction process to make data directly available to the construction site. This means that the executing firms have information to the exact position of construction elements, dimensions and other characteristics such as weight or materials. Information created during the construction process can also be stored in the GIS. This includes photos, comments as well as measurement data for the geometry produced.

RSRG customers also employ these types of information systems to run and maintain their track infrastructure. The GIS systems enables the retrieved not only of the site of individual objects, but also of detailed information such as age, type and instructions for maintenance and repair.

Digital Construction

Costing

In terms of executing projects, it is essential for customers and contractors that the costing includes all relevant outgoings and there is an awareness of when these are incurred during the course of the project.

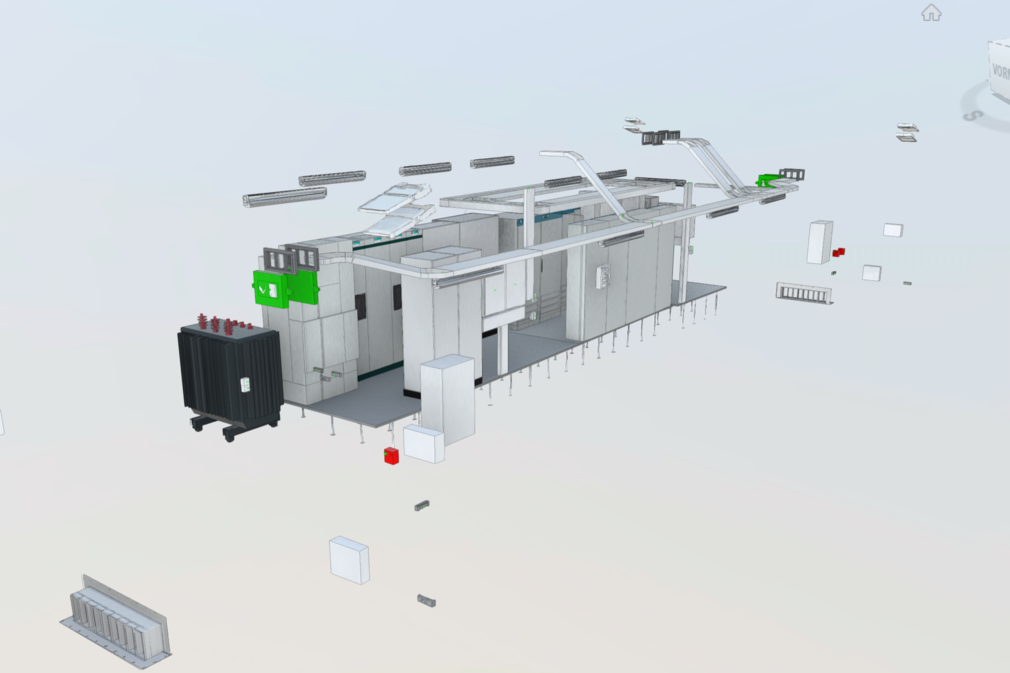

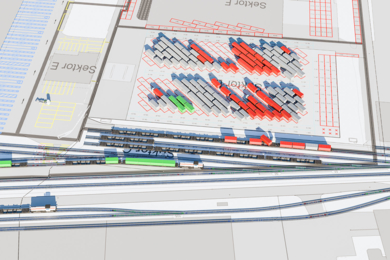

BIM gives RSRG the ability to load models into its technical ERP, so that objects can be used to determine automatic masses, create schedules of services and link these with the standard costing. Linking the construction elements with the case model allows the building construction sequence to be visualised alongside the cash flow, and to automate the settlement of accounts to a considerable degree.

This type of automation depends on the generation of standards in the modelling and the schedules of services. At this point it is necessary to have close collaboration between clients, software vendors and contractors for the long-term leverage of benefits of “Model-based costing and controls”.

Digital Engineering

The planning of the optimum construction work flow and the required resources are critical to the outcome of the project, especially during brief check intervals.

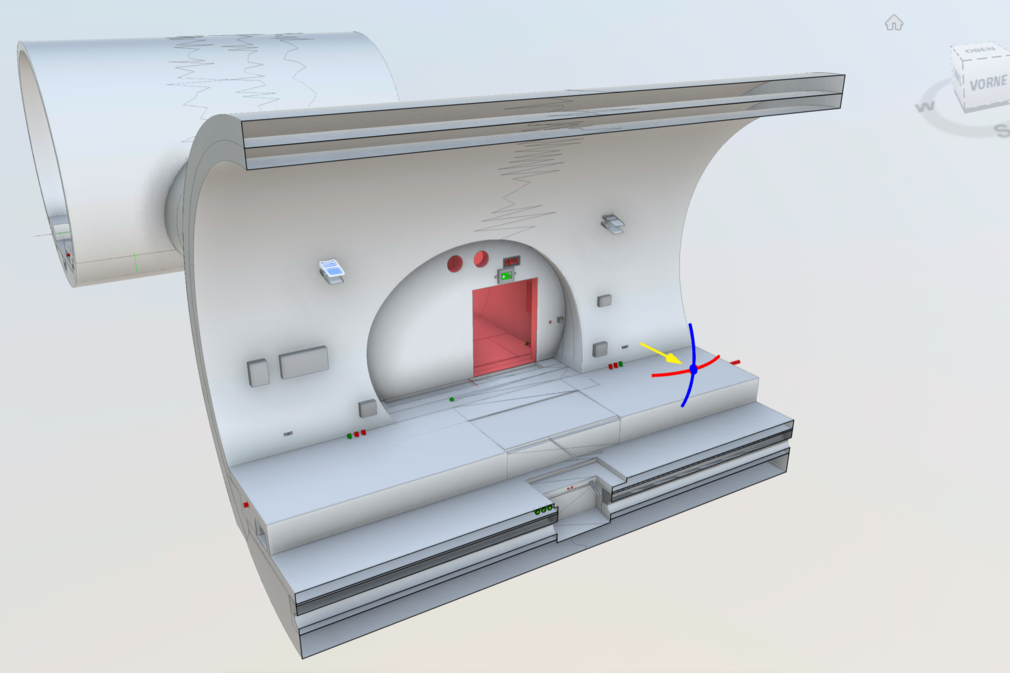

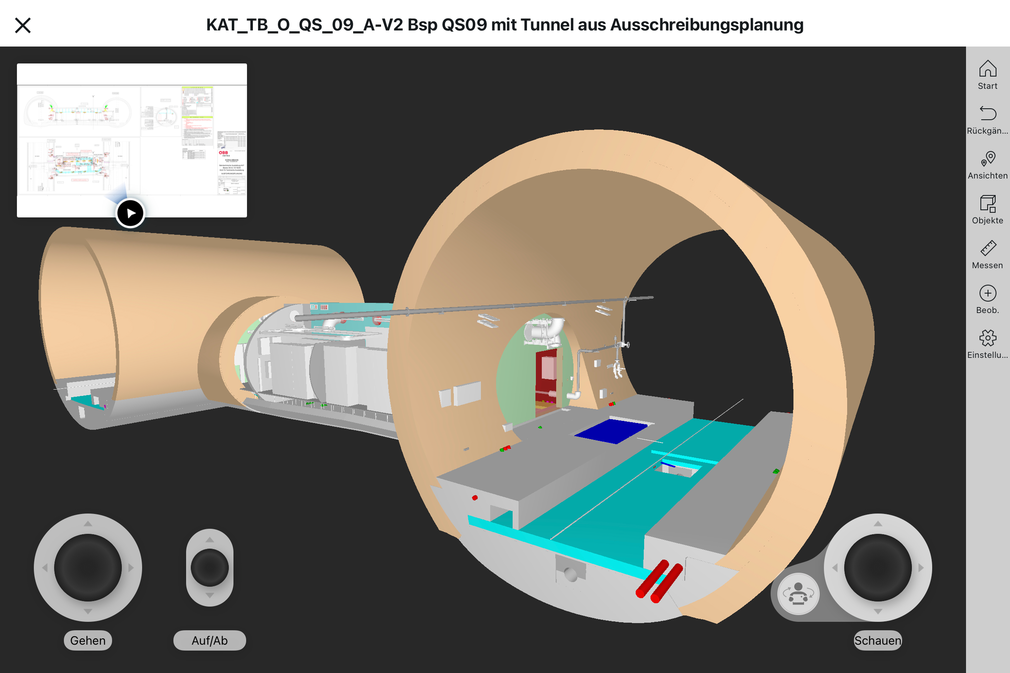

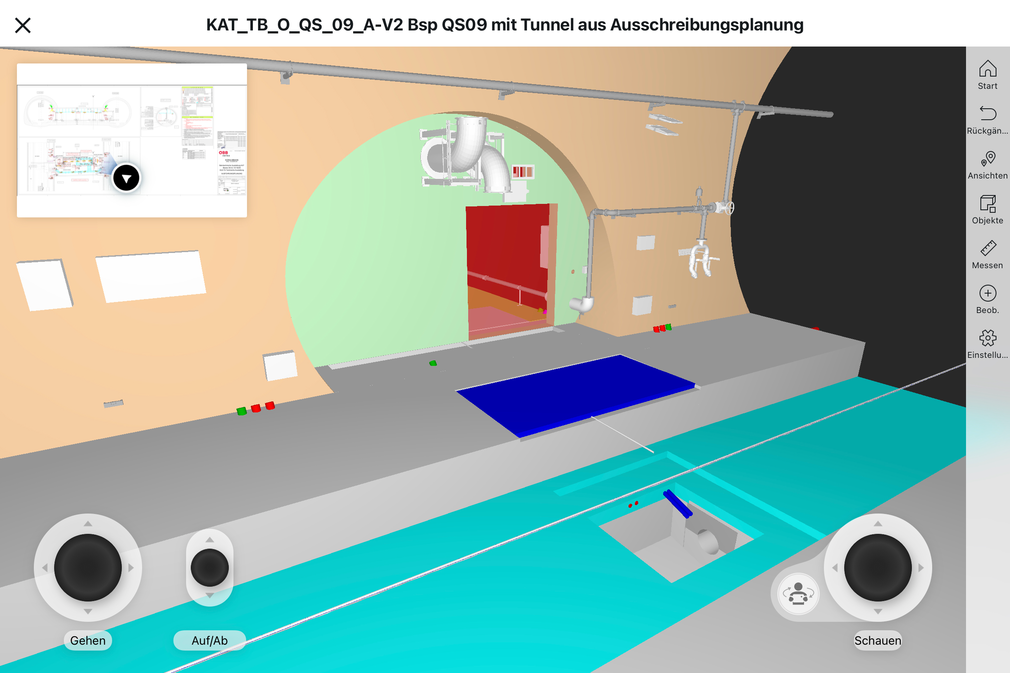

This is why RSRG relies on model-based process planning and simulation of construction processes in “virtual sandboxes”. In future, the construction projects will be structured in the model based on their individual parts (System Breakdown Structure – SBS) and linked in the software with the possible construction processes and the requisite work steps (Work Breakdown Structure – WBS). The individual work steps (sequences) contain information regarding the necessary resources (equipment and personnel). The duration of the individual work steps can be simulated, first by a simulation based on the performance data of the equipment, and second by applying outgoings based on experience. The benefit of 4D visualisation is that everyone can quickly understand the construction remit and the planning. A discussion of optimisation potentials will quickly commence among experienced experts. Alongside the visual optimisation, RSRG develops simulations based on a data model, which can be optimised in terms of various KPIs such as time, costs, CO2 consumption, resource requirements etc.

Since things frequently do not go to plan in the world of construction, RSRG using sensor technology to create a digital twin of the construction work. With the Koralm project, the rail engineering specialist has currently fitted its locomotives with GPS transmitters and RFID transponders, which relay live positional data. These log files are used to determine performance data, which in turn forms the basis for subsequent planning aspects, such as the timetables.

Digital Construction

Apart from the actual construction activity, numerous administrative tasks arise during the course of executing the project: The works are documented and accounts prepared. Construction element quality is tested and documented. The construction planning is coordinated, and updated plans, models and specifications are supplied to the construction site teams…

To facilitate this, RSRG employs construction site platforms that deliver as many functions as possible – ranging from the digital construction logbook and reporting system, to time recording, planning and model management, photo management, task management, schedule integration, structured documentation of the construction progress, right across to quality planning and quality management. The horizontal and vertical integration on the platform ensures that system discontinuities are closed, and teams, processes and information are interlinked across organisational boundaries. Subcontractors and customers are invited here to work collaboratively and transparently with the Rhomberg Sersa Rail Group. The platform’s mobile application is augmented with other connected apps, and is run on high-end devices such as tablets and smartphones to support the day-to-day activities of the construction site. The digital, systematic capture of construction site data gives customers a good overview of the progress on the construction site. The analysis of the data enhances the preparation and execution of future projects. At this point, all the relevant information of the project is delivered in real time to the parties involved.

QM – enabled by Reality Capture

There are numerous reality capture tools for use in quality assurance activities. When the job calls for high precision measurement down to the last millimetre, that is when robotic total stations are needed. Scanners deliver wide-area evidence of the correct spatial situation and the extent of individual elements. Finally, highly-complex gyro sensors/accelerometers automatically identify deviations between the TARGET and ACTUAL geometry of the track system. All of these tools are so designed that they can be set up and operated by construction personnel. The results are made available via web applications to the individuals responsible.

BIM to Field

How are tracks, the contact wire mast, the signal, the cable ducts and the bridge installed or built in the correct position? Two things are needed to achieve this. First, the planned objects must be available in the form of a model that contains all geometrical information – RSRG's surveyor prepare this part. Second, there must be user-friendly tools that the construction personnel can use - these consist of robotic total stations and centimetre-exact GNSS receivers with accompanying software. The fundamental preparations can be delivered via internet to these devices in the field.

Augmented reality is another method of using models in the field. This consists of projecting digital models correctly positioned on real images displayed on smartphones or tablets. Special glasses also enable the real environment to be overlaid with digital objects. Although this cannot achieve any precise positioning, it does however enable future or concealed construction elements to be displayed such that the relevant individuals can get an idea how the built structure will appear or where the subsurface connections are located.

Machine control system

Once the construction or building project has been conclusively defined, the BIM model is used to generate all the relevant data for the ground survey works and the 3D machine control. The work previously performed in the modelling phase means that this data can be generated automatically. The data is made available to the relevant project via the RSRG data platform, where it can be directly used by the relevant equipment. The subsequent comparison of the ACTUAL data against the projected ACTUAL data should also be automatically made available to the customer, and it forms part of the construction documentation.

Robotics

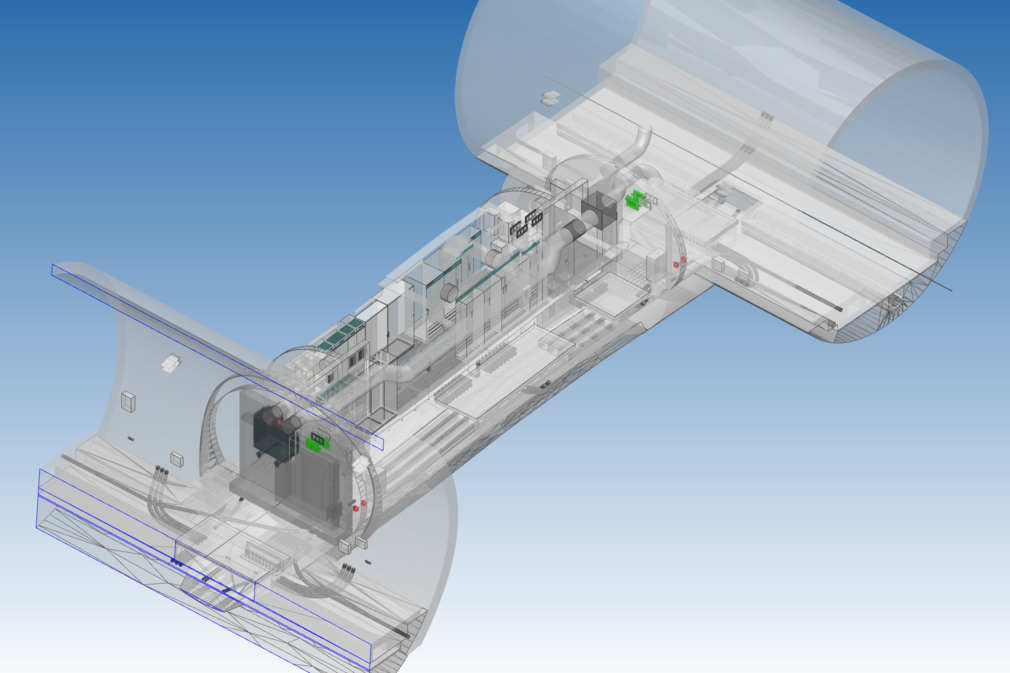

Apart from equipping conventional construction devices with machine control systems to assist the operator, RSRG is also piloting the use of autonomous robots.

The field application is the drilling of holes for the installation of electrical systems in tunnels. Multiple holes have to drilled in every metre of the high-strength, reinforced lining segments. The marking and drilling processes are still performed manually. The positioning of the holes (floor & side walls) and the vibration of the hammer driller make this work ergonomically challenging for workers. So, it is planned that these tasks will in future be performed using robotics.

The first step is to capture and model the vicinity using scanners. This is then used as the basis for creating the drilling template (positioning, angle, and diameter), and the work flow is simulated. Vector information allows an operator to control the drilling robot that drills the holes autonomously. The tests performed to date show that robotics is well on its way to becoming part of the construction site process. The technology is ready for implementation and the positional accuracy is very good. The next step will see the device technology and the processes optimised such that a wide-ranging application is also economically efficient.

Asset management

Maintenance management

At the conclusion of the project, the BIM model that has been continuously enriched across all the phases of the project, now exists in the form of an as-built model, which represents the object delivered to the customer. This will contain all the historical construction data as well as the quality assurance documentation pertaining to the specific object. The conclusive technical survey documentation also forms part of the basis of the geometrical BIM as-built model. This means, that at the end of the project the customer receives an outstandingly well-documented, digital image of the built reality.

This model can quite rightly can called the “digital model”. The persons responsible at RSRG remain a little cautious here, however: “Only when the system is equipped with the right sensors to enable permanent observation and the system's bi-directional communication with its digital image functions, only then can we talk about a genuine “digital twin”, explains Ralf Sommer, Project Manager BIM Implementation. “Right now, the model does indeed already enable our customers to have a continuous overview of the project status, and it provides the perfect planning basis for renewal works. However, BIM allows so much more to be accomplished. But we all still have a few yards to go before that point.”

Conclusion

Rail infrastructure projects are generally highly complex. In order to solve pending construction projects in the coming decades, what we need is integral project development (IPD). Apart from a collaborative execution of the works, RSRG is determinedly looking towards new technologies that can enhance levels of quality and efficiency.