The RSRG relies on modern technology and digital operations for the large-scale Austrian Federal Railways (ÖBB) project in south-eastern Austria.

Along with its joint venture partner PORR, RSRG is responsible fot the railway engineering and equipment of the Koralmtunnel, one of the largest tunnel construction projects in Austria. This complexity led t the need to bundle expertise. To achive this, the joint venture partners use innovative and forward-looking working methods of digitalisation.

More specifically, PORR and the RSRG subsidiary Rhomberg Bahntechnik are using LEAN management and BIM. Together with the expertise of the partners and their decades of experience in operations, this creates holistic added value for their customer ÖBB Infrastruktur AG.

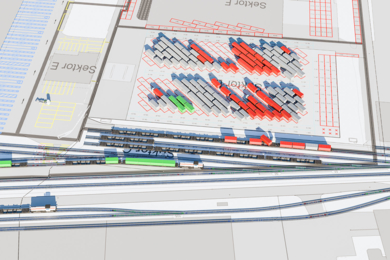

The use of BIM and LEAN management methods is indispensable in the cycle of project milestones, deadlines and construction realisation in order to ensure a transparent and structured procedure. Above all, both instruments score highly by simplifying the complex logistical construction processes as well as the ability to plan the execution processes at an early stage. The focus is on bringing together all stakeholders, the interfaces resulting from operational activities and the flow of communication.

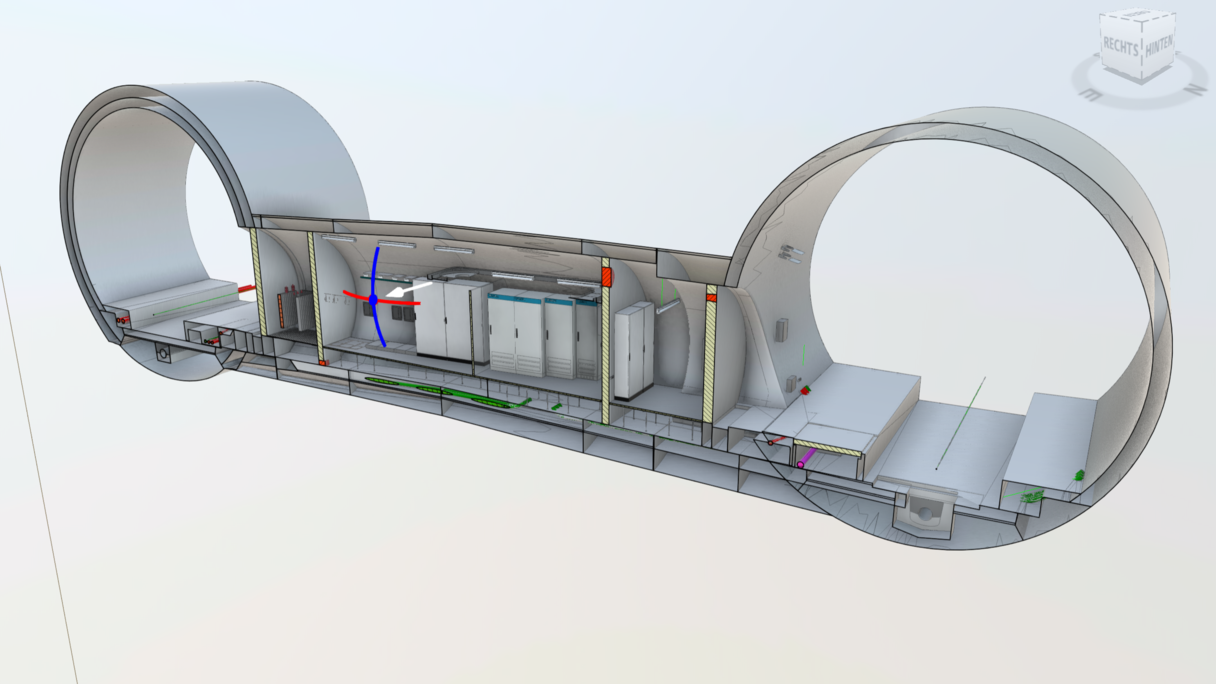

To achieve this, modelling, planning and execution are brought together in an iterative process right from the start. Simulations can be cited as an example to ensure that the seven trades from the railway engineering equipment that are to be executed together do not collide. Agile project manage-

ment is needed to evaluate the results generated and to develop appropriate measures for implementation, which in turn are evaluated at regular intervals in LEAN meetings with the project team.

Using LEAN approaches, a project team of up to 25 people is working on the Koralmtunnel, supported by digital tools, on modelling, technical and overall coordination. In addition, the service portfolio also includes internal resource planning through to project controlling. As a common basis, a value concept was created that is based on the principles and values of the team – for example, reliability and transparency, combined with a common pioneering spirit.

The model-based working method, coupled with agile project management and the value concept, leads to an improvement in the quality of planning as well as to an optimisation of the logistical construction processes, right from the start. We have already observed the first successes of this method of working: Based on the pre-defined prioritised sample cross-cuts, subject-specific facts were discussed and integrated and completed simultaneously in the three-dimensional space. Further down the line, the information generated and processed in the preparation phase of the model should also be accessible in the utilisation phase or in operation. The data is made available in a simplified and structured way. Furthermore, comprehensible data to assess the condition should be compiled and a basis for a superordinate reporting system should be created, which is handed over in the form of an as-built model.