Cutting-edge digital services for enhanced quality and efficiency in the railway industry.

We approach digitalisation throughout the entire project lifecycle. Our longstanding experience as a full-service provider allows us to create maximum benefit for all project participants through a unique combination.

We understand that digitalisation and Building Information Modeling (BIM) lead to better solutions in railway construction. Our goal is to maximise customer benefit while elevating the quality and efficiency of our services to a new level. By leveraging the advantages of digitalisation and focusing on the entire project lifecycle, we maximise the potential for all project stakeholders.

Our extensive experience as a full-service provider in railway construction gives us deep insights into the needs of each project phase. This allows us to have a very accurate picture of the challenges and opportunities for both ourselves and for our customers. With this unique wealth

of experience, we can drive innovations that deliver significant added value for all. This is innovation in practice, for practice.

With this conviction, we began implementing digitalisation and BIM in 2018. The result is products and services that provide exciting added value for both us and our customers. What works successfully for us is also of great value to our customers.

In line with the concept of “along the lifecycle,” we present the areas of Digital Rail Services and their developments or projects below.

REALITY CAPTURE

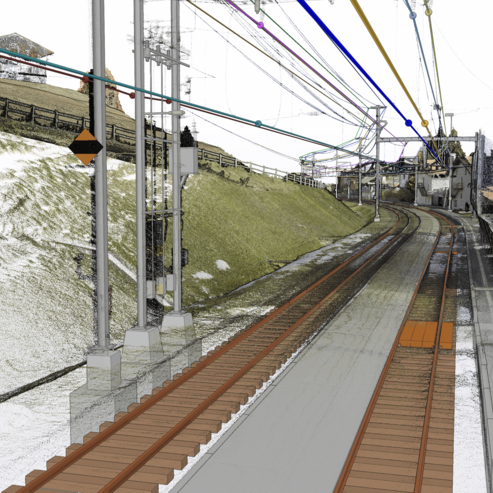

Digitising existing infrastructure as documentation and basis for comprehensive evaluations and analyses.

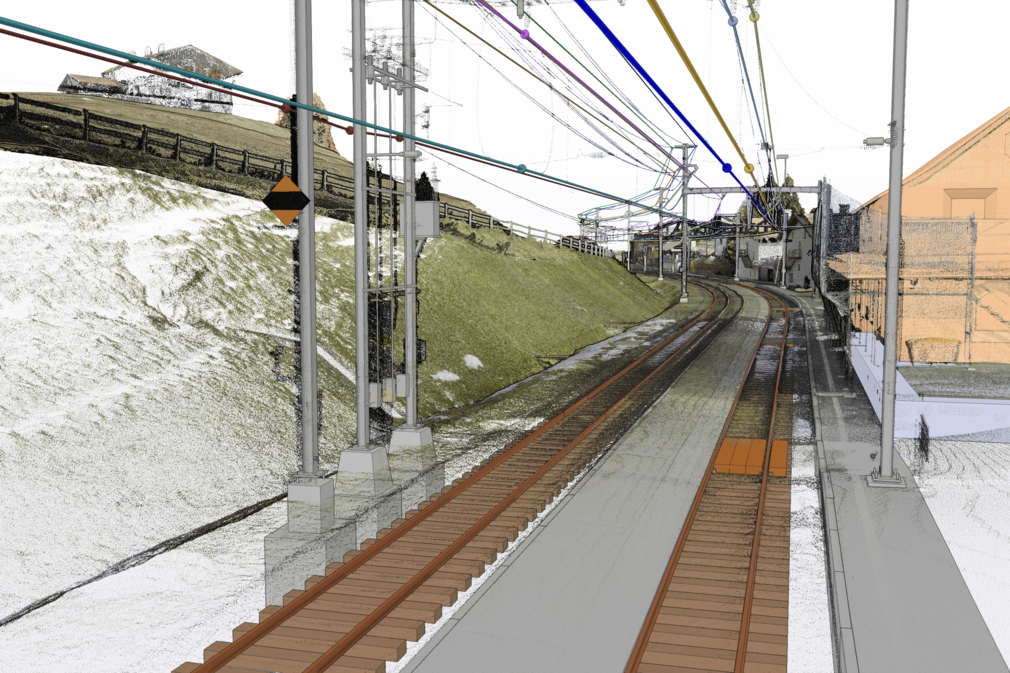

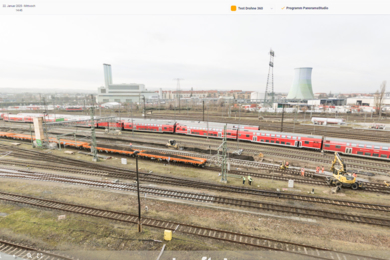

New or upgraded railway infrastructure rarely occurs on a greenfield site: existing facilities often need to be renewed or expanded. Therefore, information about the existing infrastructure is crucial for planning or preparing the construction site. Our Reality Capture services efficiently and accurately capture and digitise these facilities and their surroundings.

From classic point surveying to 3D measurement with drones and laser scanners to rail-bound mobile mapping, we can respond to various requirements and conditions. Additionally, the further processing and publication of the results in the form of orthophotos, point clouds, or analyses are individually tailored, enabling seamless workflows.

High-quality survey data also forms the basis for advanced products like BIM models of existing conditions or clearance analyses, which we can offer from a single source.

DIGITAL CONSTRUCTION SITE

Increasing efficiency with digital tools.

Digital planning and construction, combined with the BIM philosophy, represent the leading-edge working methodology for today’s construction projects. The tasks on a railway construction site are demanding and require a high level of specialised competence from the site personnel. With digital tools and the corresponding data from planning and/or Reality Capture, work preparation, construction execution, and measurement can be simplified. Central to this is the digital information flow, ensuring that necessary documents are accessible to all project participants at any time and place. The digital construction site also aims at continuous process optimisation, considering all market-relevant solutions. Sensor technology on construction machines, visualizations using AR or VR, and model-based surveying are just a few examples of topics the Rhomberg Sersa Rail Group consistently promotes.

BUILDING INFORMATION MODELING

Digital from start to finish.

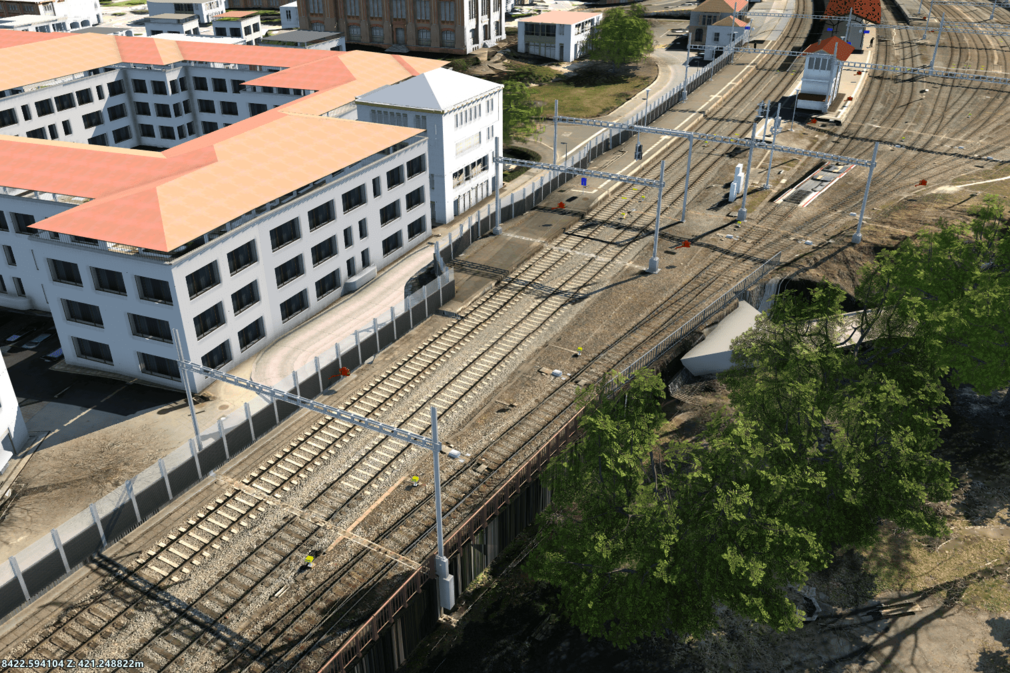

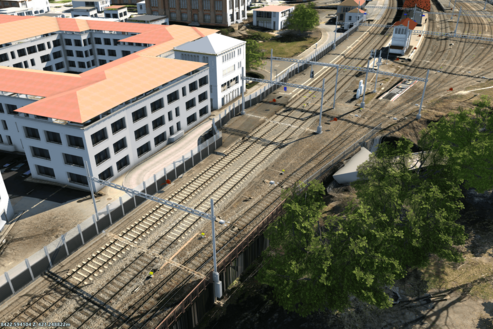

Just like a real structure, its digital twin also goes through a lifecycle. The project's phase determines the requirements for the model and its contents.

The existing conditions model is the starting point of any BIM project, offering optimal information quality for all project participants. Initially, an accurate recording of the current situation within the project perimeter is conducted (Reality Capture) and combined with existing data and information to form a 3D BIM model. The procurement of additional data depends heavily on its availability in the customer’s systems and can range from direct database access to manual collection. Thus, we proceed carefully to incorporate only reliable data with corresponding source information into a foundational model.

Our customers trust the quality of our existing conditions models. Using the latest technological developments, we provide comprehensive information to all project participants. Digital foundations, particularly 3D existing conditions models, have become a crucial part of project planning in the railway industry.

Based on this existing conditions model, further planning, execution, or integration into an operator system can commence. During project processing, a BIM model achieves its highest “information status”. Ideally, all relevant data is structured and accessible through this information model, usable by various project participants. Upon completion of construction activities, information about the actual built structure (exact position, materials used, etc.) is recorded in the model. From this point, we refer to it as the “As-Built Model,” handed over to the client according to their requirements, who then transfers the data into their asset management systems.

The “Rail Asset Hub” of the ARGE Track Diagnosis offers support here: facilities and their properties are stored in INFRALIFE©. Condition data, such as track geometry or rail profile wear data, is ideally collected regularly, analysed in the IRISSYS© analysis platform, and used to develop appropriate measures. This allows the behavior of the facility to be tracked and optimised over its entire lifecycle.

All information is quickly and easily accessible via the Track Diagnosis Dashboard. To support the representation of the information, infra3D can be used to conduct a virtual site inspection directly from the workplace.

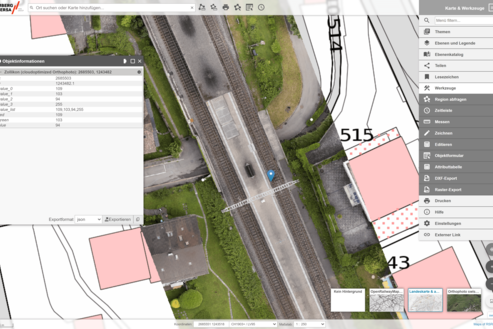

GEODATEN

Brought to life.

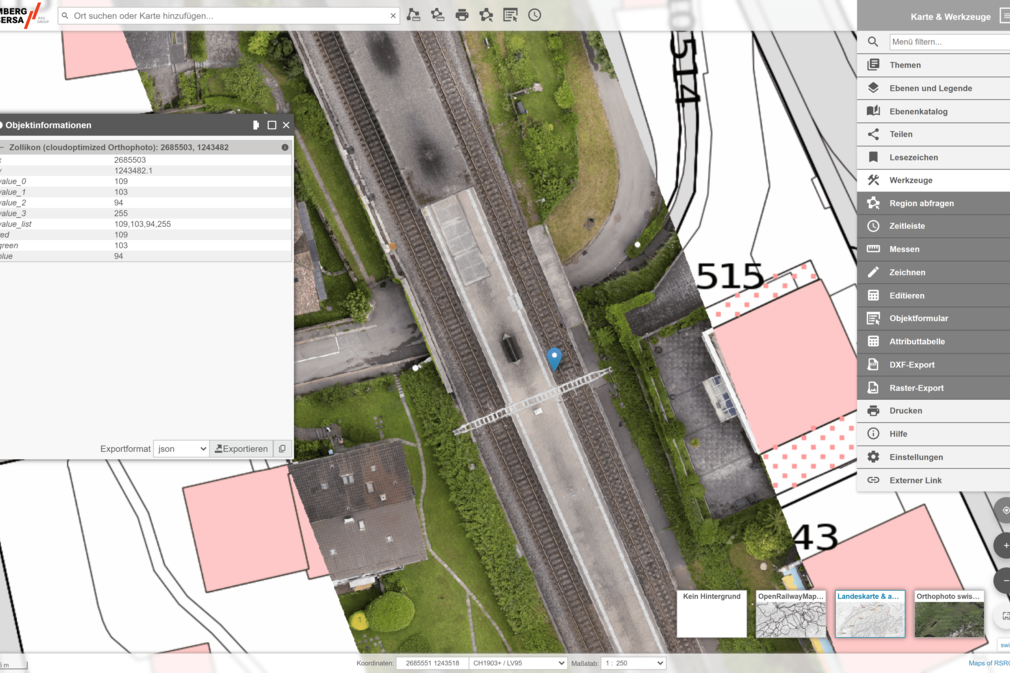

Geodata is ubiquitous today, even in the everyday business of RSRG: execution plans, stakeout points, machine control, survey recordings and more, all contain and generate spatial information and are essential for our construction sites. However, they are still often used statically as paper plans or digital PDF files. With changing requirements, increasing data volumes, and growing task complexity, this reaches its limits. A static plan can only represent a limited amount of information. An interactive web-map solution, a WebGIS, can combine, overlay, and filter project-related and general geodata such as terrain, nature, or water protection zones as needed. Insights are gained from spatial context information and possibly directly recorded in WebGIS. Recently, internal and external project staff can interact with data and maps in the in-house WebGIS, efficiently handling projects together.

CONSTRUCTION PROCESS AND LOGISTICS SIMULATIONS

Efficient construction site thanks to 4D construction planning.

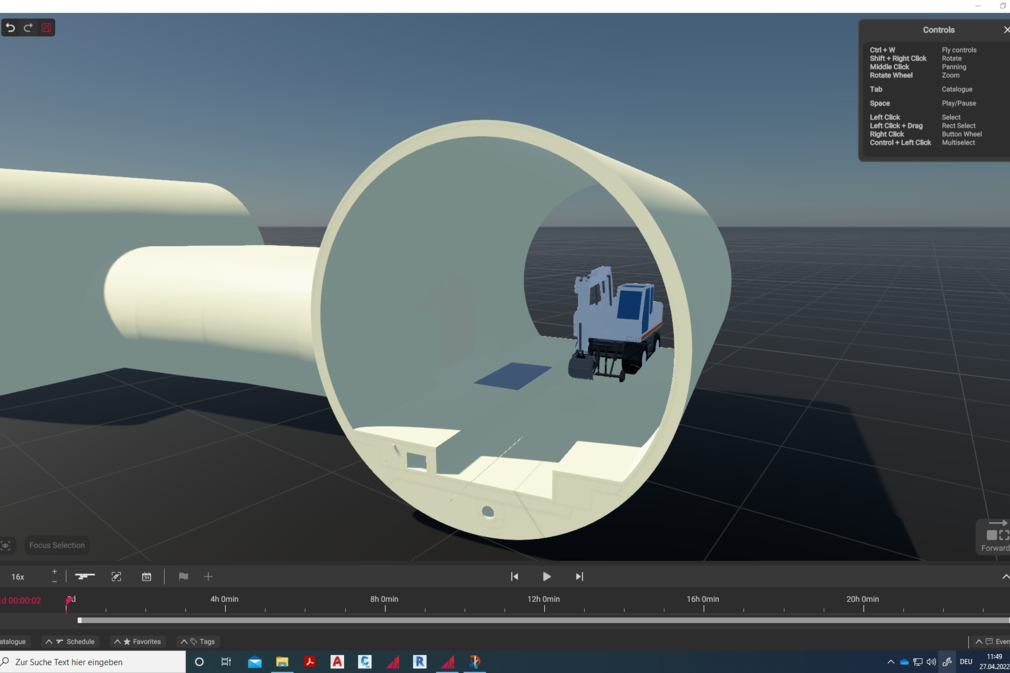

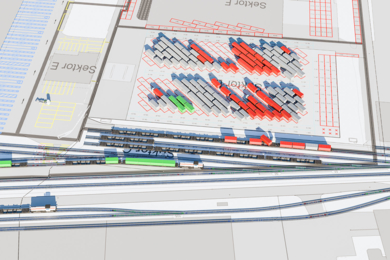

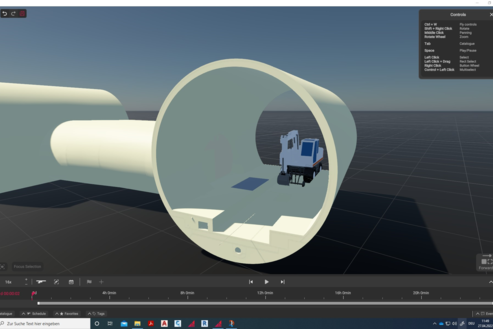

In cooperation with BII GmbH, RSRG has developed an in-house software solution for visual planning and preparation of construction projects. In a created BIM model – essentially in the “digital sandbox” – all construction and logistics processes are planned, simulated, optimised, and compared. The resources used, such as equipment and machinery, are tagged with the same cost and performance values used in our traditional costing department. The result is a complete visualisation of the entire construction process, which becomes a central information and communication point for all project participants. Additionally, with the completed construction schedule, we automatically have large amounts of data available from which we can derive and provide schedules, cost estimates, resource needs, material flows, CO 2 consumption, etc. A variant comparison could thus, for example, show the general feasibility as well as the respective impacts on costs, deadlines, and CO 2 emissions.

At the heart of this comprehensive software solution is the visual aspect, which immediately raises all project participants to a very high level of information and enables highly efficient and targeted discussions. Potential problems are identified directly and coordinated with the correct interfaces. Project understanding during safety briefings on construction sites is enhanced, and risk is minimised. Even those not directly involved in the project, such as local residents, can be informed in a simple and understandable way. The results of these simulations help to overcome the diverse challenges in projects and optimally support the project team –from work preparation to project completion.

Learn more

Learn more about Digital Rail Services here.