Our Employees Make the Difference.

1. Self-surveying

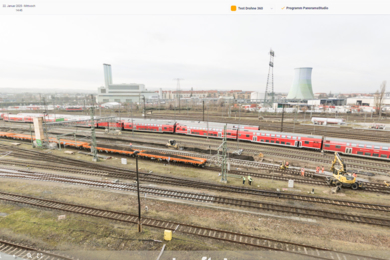

Success story: as a part of RSRG's digitalisation process, construction personnel have developed the skills to carry out surveyin tasks without the need for an external surveyor.

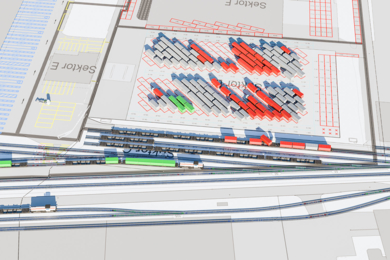

Track construction projects cannot be planned down to the last detail, and therefore require a high level of interaction between the various parties involved. A significant advantage for the smooth operation of a construction site is the reduced, or even eliminated, need for coordination with an external surveying office. A construction manager must coordinate numerous trades every day and therefore react flexibly to changes such as delivery difficulties or the availability of construction sections. Therefore, to be able to carry out measurements independently and immediately is of enormous benefit to all parties involved.

A prerequisite for self-surveying is the availability of verified basic data. This data is prepared by the "Reality Capture Team" of the "Digital Rail Services" department before the start of construction. Once this quality check has been carried out, the data is made available online. Afterwards, the construction site personnel can independently carry out axle-related measurements and stakeouts. The processes have been optimised to such an extent that any support and also the data transfer works online. Quality controls are also carried out independently and continuously in all phases of construction. Even the highly accurate fine adjustment of the rails is carried out by the construction site personnel.

The ability to carry out such measurements independently not only has the direct effect of being independent from external services, but also has indirect effects on understanding the necessary conditions for precision. This seamlessly integrates the associated processes into the entire construction process. Self-surveying thus radically increases efficiency.

2. NewTeam

The world of rail construction and maintenance has always been an industry that demands efficiency, precision, and safety. For decades, the rail industry has undergone rapid change, with technological advancements paving the way for a more efficient and reliable rail network. In recent years, the industry has seen an unprecedented shift towards digitalisation.

Rhomberg Sersa Australia has just launched a new Digital Rail Services Team. One of the primary goals of the new team is to work closely with Rhomberg Sersa Australia's operating divisions to identify pain points in their operations and find ways to overcome them. By doing so, processes can be improved and Rhomberg Sersa Australia can ensure that their operations run as smoothly as possible.

Currently digital rail services are focused on the below initiatives;

- iPhone lidar for project documentation and stockpile volumes

- Track measuring systems including trolleys and drones

- Site positioning systems for progress tracking and quality assurance

- Data sharing to keep stakeholders up to date with projects etc using cloud technology

In conclusion, Rhomberg Rail Australia's digital rail services team has already been instrumental in driving innovation and efficiency within the company's operations. By embracing technology and leveraging the expertise of the team, Rhomberg Sersa Australia has been able to find new solutions to traditional challenges and improve the safety and reliability of the rail network.