RSRG combines the advantages of a ballast track with those of a slab track.

Railway engineers have developed two fundamentally differenz superstructure systems for typical mainline and branch line track construction: the classic ballast track, which has been the standard solution for the construction of rail-bound infrastructure for around 200 years, and the slab track, which was developed around 40 years ago and has a fundamentally different structure to the SchO due to the increased demands on the track (axle loads, train sequence, speed, etc.).

Compared to slab track, ballast track has the advantages that it is 50-70% cheaper to produce, produces significantly fewer CO2 emissions and has a very simple structure. The disadvantage of the system is that it has a floating bearing (sleeper on ballast) and thus allows settlements due to the dynamic loads from the train traffic. However, these track settlements can only be permitted up to a certain extent (SR Lim). As a result, the track structure must be tamped and straightened at specified intervals to ensure operational safety.

On the other hand, the slab track has the advantage that its very rigid structure does not allow for any settlements, which means that the track gradient always remains constant. The maintenance and upkeep of slab track is therefore very low. Tamping and straightening slab track would be impossible from a structural point of view anyway. Compared to ballast track, the disadvantages of slab track include the 100-200% higher investment costs, the long construction period and the costly repair work in the event of an accident.

LMS basic idea and development

There are therefore both advantages and disadvantages to both superstructure systems. The basic idea for the development of the LMS was to combine the advantages of both ballast track and slab track in a new superstructure system that uses existing construction materials and components approved by the Federal Railway Authority in order to condense the approval procedure, which is both time-consuming and costly.

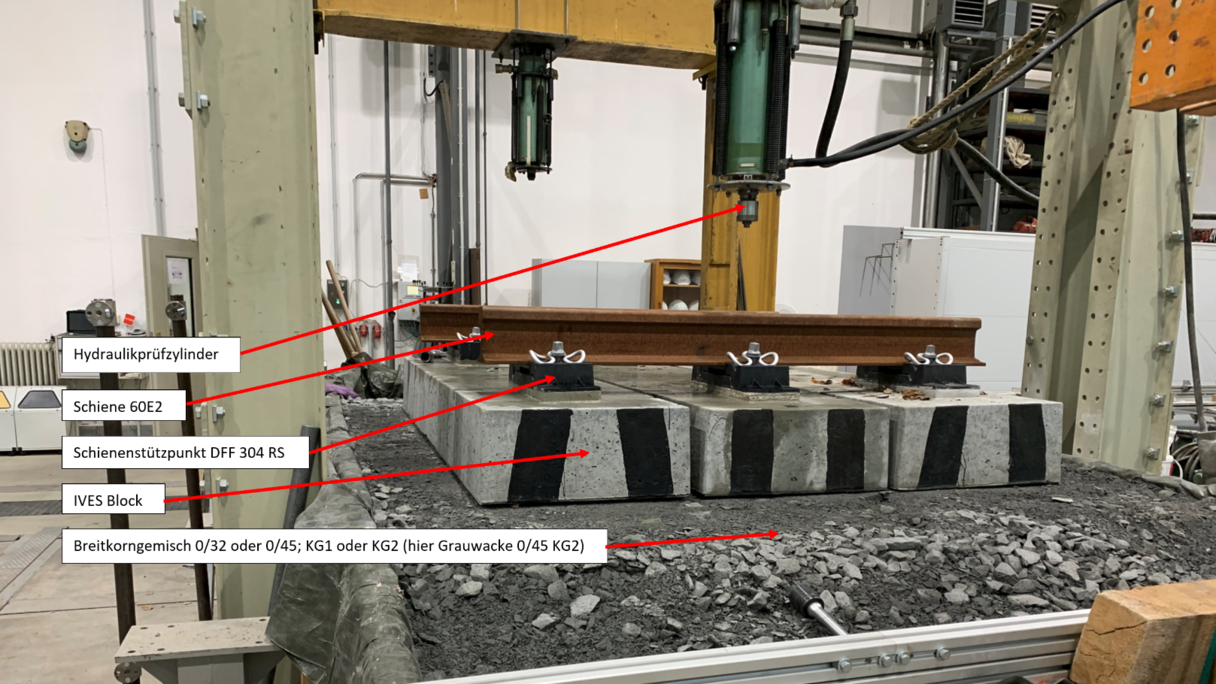

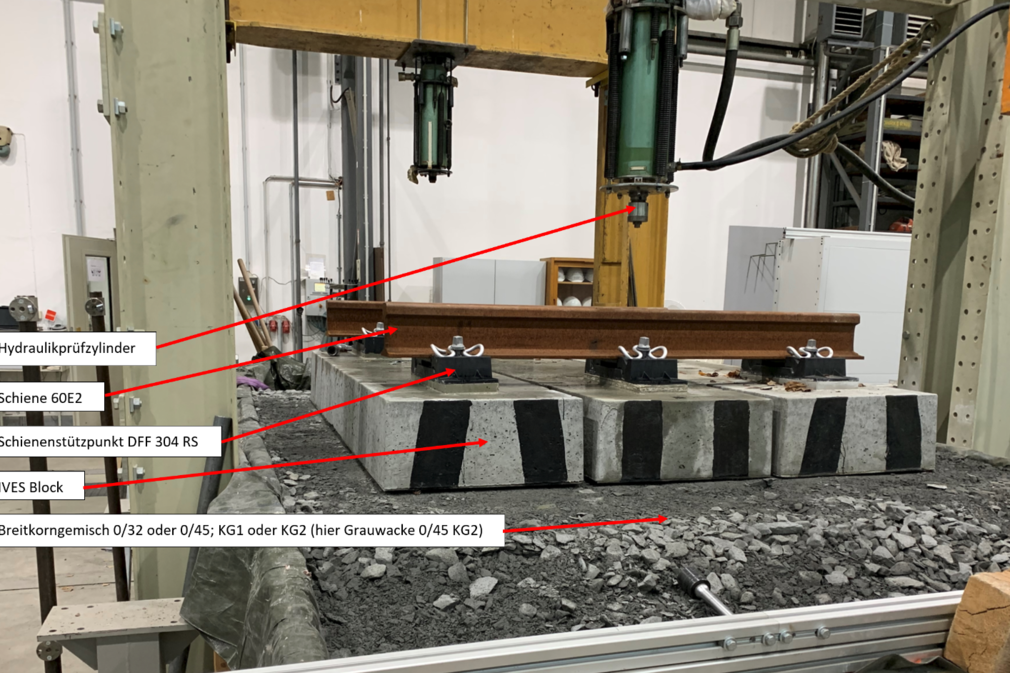

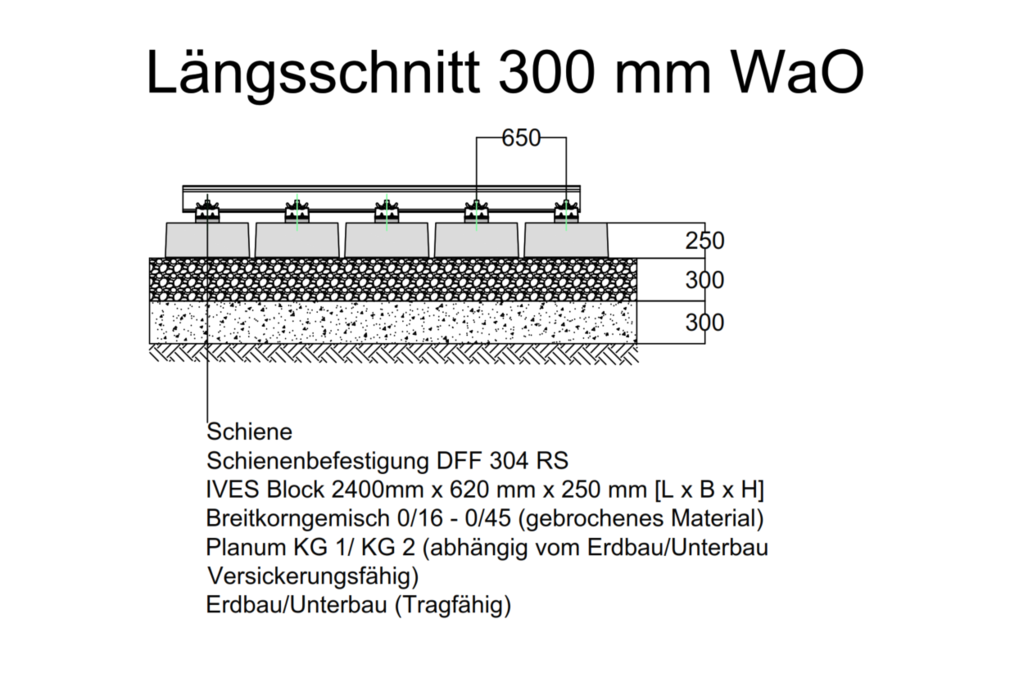

The LMS structure consists of the components shown in Figure 1. This implements the requirements of the load-bearing structure of the railway body including the base layers in accordance with DB AG Guideline 836. On top of the formation protection layer, the broad gravel mixture with a grain size of 0/16 to 0/56 (KG 1 or KG 2) is then laid in three layers and compacted. The difference to the ballast track lies in the absence of the “classic” floating ballast storage. In the LMS, these tasks are fulfilled by the broad gravel mixture with a compression of 120-150 MN/m2. IVES slab track components are used for the sleepers and rail fastenings. The RTS blocks are placed on the broad gravel mixture, the DFF 304 RS rail support points are aligned together with the rail on the track nominal gradient and grouted with a high-strength grout.

The advantage of the LMS is that the investment costs, construction time and construction risks are significantly lower than those of a slab track. The maintenance effort is also considerably reduced as the superstructure is not floating and the broad gravel mixture has a lower surface load due to the use of wide sleepers. The usual tamping and straightening work is no longer necessary.

Outlook and goal

The RSRG has applied for a patent for the new LMS superstructure system at the European Patent Office and is currently undergoing a large number of approval tests (see illustration) in cooperation with the Technical University of Dresden. Due to the promising and positive test results, the engineers responsible are aiming to apply for approval for operational testing by the Federal Railway Authority at the end of the fourth quarter of 2022.

The new LMS has the potential to gradually establish itself as a new, low-maintenance track construction system among railway infrastructure companies as a result of the expected climate changes and thereby enable more sustainable and environmentally conscious construction and operation of railway transport facilities.