RSRG is developing pioneering solutions for railway superstructure with a focus on maximising customer benefits.

The Track Superstructure Products division is responsible for developing solutions for railway superstructure. Decades of experience in the construction and maintenance of railway infrastructure at RSRG are combined with new technologies and modern approaches.

The primary focus is on maximising customer benefit. Products and solutions that are meaningful and provide added value to our customers are always the clear goal.

Currently, the superstructure products portfolio includes two main product lines: the IVES slab track system and the V-TRAS universal transition module. Both products are fully developed and have already been used in various projects. Concurrently, we are continuously improving our products as well as incorporating feedback from construction sites and operations into product revisions. This ongoing process ensures our solutions get better year by year. A stringent R&D process ensures that products and solutions are developed to be applicable in as many markets as possible. This approach ensures the scalability of our products while taking into account local conditions in different markets and making adjustments to the products as necessary to meet these conditions.

1. WAO (Low-Maintenance Superstructure)

News about Low-Maintenance Superstructure (WaO)

In a previous issue of “keep track” (2022 edition), we reported on the so-called Low-Maintenance Superstructure: a system that combines the advantages of ballast track (SchO) and slab track (FF).

The “WaO effect” is achieved by directly reusing the old ballast, processing it into a broad-grain mixture, and reinstalling it on-site as an unbound base layer, significantly reducing the necessary transport per track kilometre.

There are now important updates: In a Master's thesis from TU Dresden (Author: J. Steinbicker), we compared the CO2 balance of WaO with other superstructure systems. The result: Due to its long lifespan and low maintenance requirements, WaO performs very well compared to SchO, with around 40% less CO2 emissions per year.

Furthermore, after extensive laboratory tests, WaO has been submitted to the German Federal Railway Authority (EBA) for approval for operational testing. Once this hurdle is cleared, the system can be used in a real test track.

2. IVES (FF system IVES)

Stop maintaining, keep moving. Go IVES!

There is also very good news about our FF system IVES: The operational testing, which lasted for five years (from 2018 to 2023), was completed at the end of 2023. During a night closure, a delegation consisting of EBA, Deutsche Bahn, Vossloh Fastening Systems (VFS), TU Darmstadt, and of course, Rhomberg Sersa Rail Group, visited a site to verify the quality of the IVES system installed in 2018.

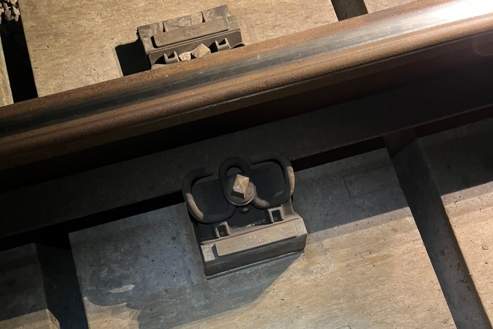

During the inspection of the Zierenberg Tunnel, which is located near Kassel and is nearly one kilometre long, our FF system was thoroughly examined by all parties involved. Each support point (model DFF 300 RS) was individually examined, and each supporting element was carefully inspected.

After several hours on the track, it was clear: The system is in the best possible condition, and from a superstructure perspective, there are no obstacles to the safe, long-term operation of the Kurhessenbahn. Based on the positive findings of the operational testing, the general approval for IVES for the DB InfraGO (formerly DB Netz AG) network will be granted this year.