Pilotproject

Rhomberg Sersa Deutschland uses 3D machine control for the first time.

The challenges of the ‘Weidenthal-Hochspeyer and the opposite track formation protection layer’ construction project were tough: the programme included the removal of 2,000 m² of rock and the installation of approx. 1,000 tonnes of FPL and ballast, each within 88 hours.

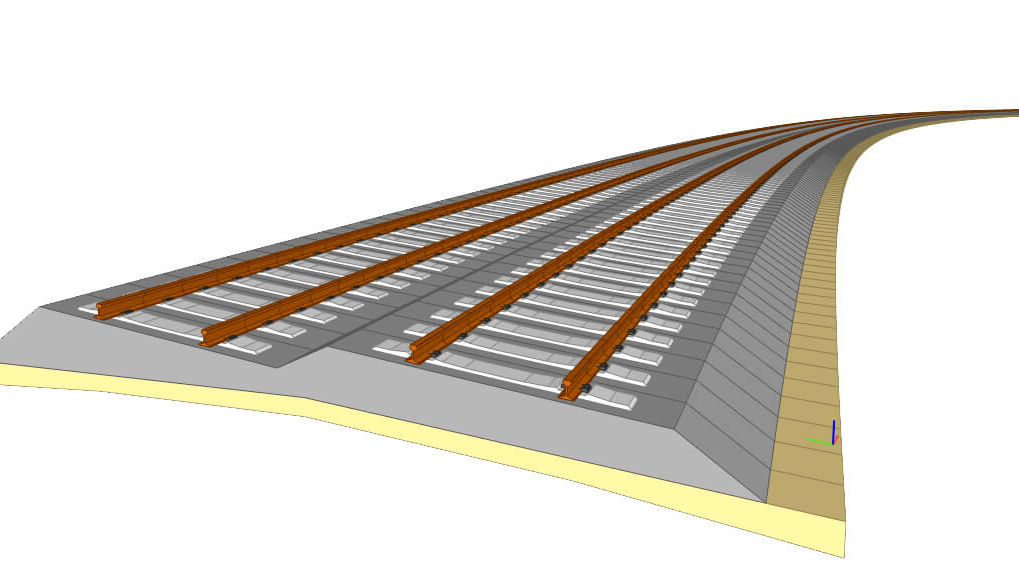

To cope with these tasks, Rhomberg Sersa Deutschland used a bulldozer with 3D machine control system for the first time. The colleagues on location were supported by the RSRG internal BIM team which created a digital terrain model of the track section with all necessary details. A Cat D4K dozer with 3D ATS total station, which compares the received actual values with the target values of the terrain model in real time and therefore regulates with millimetre precision, was used for the implementation. The result: the client, DB Netz AG, received a firstclass product within the specified time.