Modular lifting and aligning systems for every track construction challenge.

For over two decades, the lifting and aligning systems developed by Rhomberg Sersa Rail Group have been in use worldwide – both in our own projects and by clients and infrastructure operators.

Their unique selling point: stress-free track alignment and free passability under axle loads of up to 2 tonnes, made possible by aligning directly at the rail. This combination ensures maximum efficiency and flexibility on construction sites around the globe.

As one of RSRG’s core products in the field of track construction, the systems undergo continuous and systematic development – always with a focus on the specific requirements of projects and clients.

A current example is the expansion of the RS RhoSAS turnout alignment system. For a local transport project in Nuremberg, the system was enhanced with modular track gauge rods. Despite the very low installation height of approximately 35 mm, it allows for highly precise positioning and alignment of the turnout at individual support points without needing permanent gauge rods.

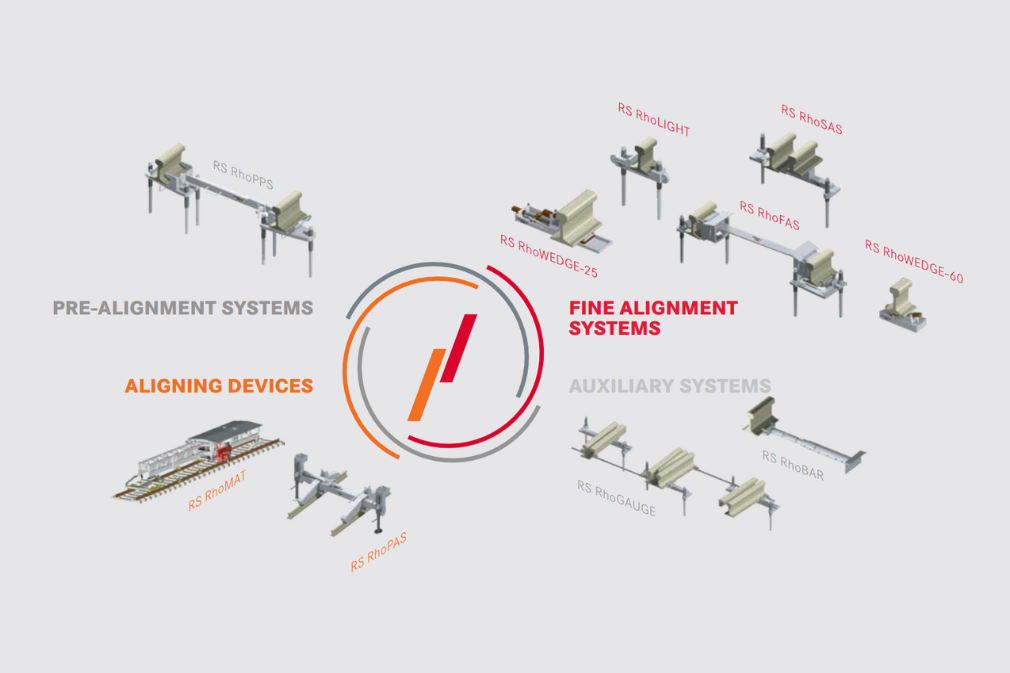

The RSRG lifting and aligning system family includes a total of four fine alignment systems for tracks and turnouts, supplemented by a pre-alignment system and various auxiliary components such as side supports and gauge rods. Thanks to this modular approach, an optimal solution can be offered for almost any track system with free rail access.

The range of alignment aids extends from simple manual jigs to tachymeter-controlled alignment robots.

These high-tech solutions from RSRG significantly simplify the alignment of track panels. However, one thing remains true: the experience and know-how of the professionals operating these systems continue to be key to their success.