Rhomberg Sersa UK: The Trusted Partner in UK Rail Infrastructure

Rhomberg Sersa UK (RSUK) is a tier one railway engineering service provider that uses the best available technology and people. They have been working with UK rail infrastructure owners and private infrastructure owners (e.g. freight lines, light railway/trams, industrial sites and ports/harbours) since 2014 to create safe and reliable rail networks. Rhomberg Sersa UK is a trusted partner, because they provide effective solutions that meet their customer’s needs. Their service offering includes the following:

- Design/Construction of slab track and ballasted track solutions

- Rail infrastructure renewal and maintenance

- Rail Engineering, Ground Investigation and Geomatics Consultancy

- Specialised OTP and OTM

Facts and figures

- Established in: 1999

- Members of Staff: 48

- Locations: Doncaster, Chesterfield, Wigan, Dartford

Quality, Certificates & Accreditations

Rhomberg Sersa UK ensures success through strict compliance with statutory legislation and the auditable standards identified by Network Rail, RSSB, ISO 9001, ISO 14001 and OSHAS 18001. Their formal integrated management system has been created to ensure compliance with these standards and enable their team to manage the company’s health and safety responsibilities and their commitment to environmental protection. Like all well-established management systems the core is based on the Plan, Do, Check, Act approach so that it achieves a balance between the systems and the behavioural aspects of management.

What’s Been Going on?

In September, we moved our Southern office a short trip up the M25 from Sevenoaks to Dartford. The location of the new office is at Dartford Business Park, near Dartford Train Station. The lovely new offices, see pictures below, provide easier access to the routes that we maintain on the Network Rail South East Minor Works Framework.

RSUK hold a full Principal Contractor’s Licence (PCL) from Network Rail. The award of a full PCL recognises our ability to safely and effectively deliver rail infrastructure projects and validate our competence in a live project scenario.

In the UK, we have one of the most diverse and inclusive workforces in the rail industry. Our approach is championed by everyone, but one of our leading lights in EDI is Misbah Syed, Assistant Project Manager, working as part of our national project management team. Misbah is passionate about equality, diversity and inclusion. She actively promotes the message of a positive contribution from everyone in our workforce. Misbah was recently made a “Women in Construction Ambassador” by the London Build Show, see below.

Case Study: Mountfield Tunnel

In 2020, we were commissioned by Network Rail to deliver works on the Southern Slab Refurbishment Project. This project involved the delivery of GRIP 2-4 on life expired slab track in two areas and GRIP 5-8 on a stretch of slab track with life expired plain line components.

This case study describes our GRIP 2-4 works at the 483m long Mountfield Tunnel, which came into service in 1852. The tunnel was originally installed with ballasted double track, which was converted to a single track slab track in 1975.

These works were scheduled to begin in 2020, but were delayed by COVID-19 restrictions. We planned to mobilise in September 2020 to carry out the agreed works, but during this period Network Rail’s Track Maintenance Engineer found that the slab in the tunnel had started to fail. This caused severe alignment errors leading Network Rail to impose an Emergency Speed Restriction (ESR). We worked with Network Rail to carry out temporary emergency repairs:

“During my tenure as Route Access Manager Track, South East, I had occasion to call on the services of RSUK. A recent slab failure at Mountfield Tunnel required an ESR, RSUK responded immediately to our request for support and provided solutions for emergency repairs. They worked collaboratively with us to mobilise site teams for the first available access within 24 hours to undertake temporary works to stabilise the slab. This allowed RSUK to develop and implement other repairs during follow up possessions whilst also developing a long-term solution. The successful intervention saved significant costs in potential delays and supported the removal of the 20mph ESR”

Philip Jeyes, Asset Strategy Manager Track, Network Rail Southern Region

Following completion of the emergency repairs, we were able to begin our GRIP 2-4 works on Mountfield Tunnel. Network Rail planned to replace 230m of slab track in CP7 (2024-2029) at Mountfield Tunnel. However, the poor condition of the slab track meant that a 50m stretch of track required immediate replacement.

After completing track/tunnel surveying and review of our findings, we generated nine options for renovation or renewal of the slab track in Mountfield Tunnel:

- Manage current installation through ongoing maintenance

- Base plate patch and repair

- Removal of PACT and Installation of New Baseplates on RC Slab

- Precast Slab Track on top of existing RC Slab

- Porr STA on New RC Slab

- IVES on roller compacted concrete pavement

- Frame Track on discrete foundation (Piles)

- Twin Track with Narrow PORR STA on New RC invert

- Twin Track with tunnel enlargement and relining

Network Rail accepted the IVES on roller compacted concrete pavement option and RSRG UK mobilised to deliver the first half of the tunnel within a 9 day blockade in October.

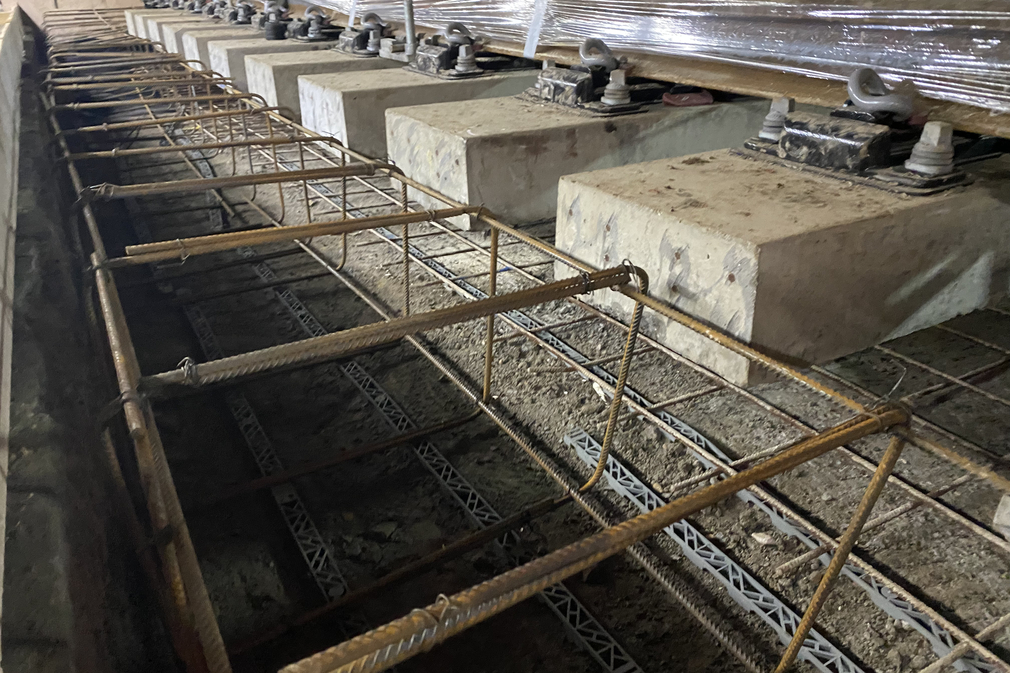

However, 2 weeks before the commencement, additional asset information revealed concerns that the existing slabtrack was acting as a structural prop to the tunnel. Therefore, a new design and methodology, for installing a insitu cast slabtrack solution, working temporary works was developed and implemented to deliver the worst 30 m of track at the tunnel portal that required immediate replacement to prevent closure of the operational line along with repair of the existing tunnel drainage system.

The works were delivered in full scope and handed back on time, with the team delivering the revised project from concept, remit, design through to completion of installation within 25 days. The track was handed back at full line speed preventing further impact to the operational network.

Contact