Rhomberg Sersa Rail Group uses BIM to develop the perfect construction process.

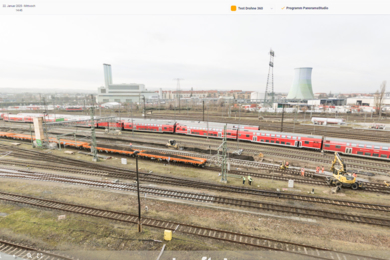

Anyone going to an Impro Theatre looks forward to spontaneous performances, unforeseen twists and turns, as well as entertaining chaos on stage. Those in charge of a railway construction site hope for the exact opposite: clear procedures, reliable deadlines and the ability to plan. Unfortunately, reality is often enough more like the former scenario than the latter. With state-of-the-art technology and the advantages of digital applications, the RSRG has now set out to unite vision and reality.

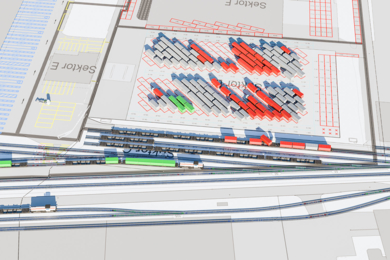

To be specific, the team in charges plans to identify the optimal construction process in a "digital twin" in the future. The 3D structure, i.e. the BIM model, and the environment will be imported into a "digital construction process planning" to achieve this. "Our goal is very clearly to first build complex projects virtually and only after that in reality," explains project manager Ralf Sommer. "This way, we can avoid unnecessary improvisation as much as possible."

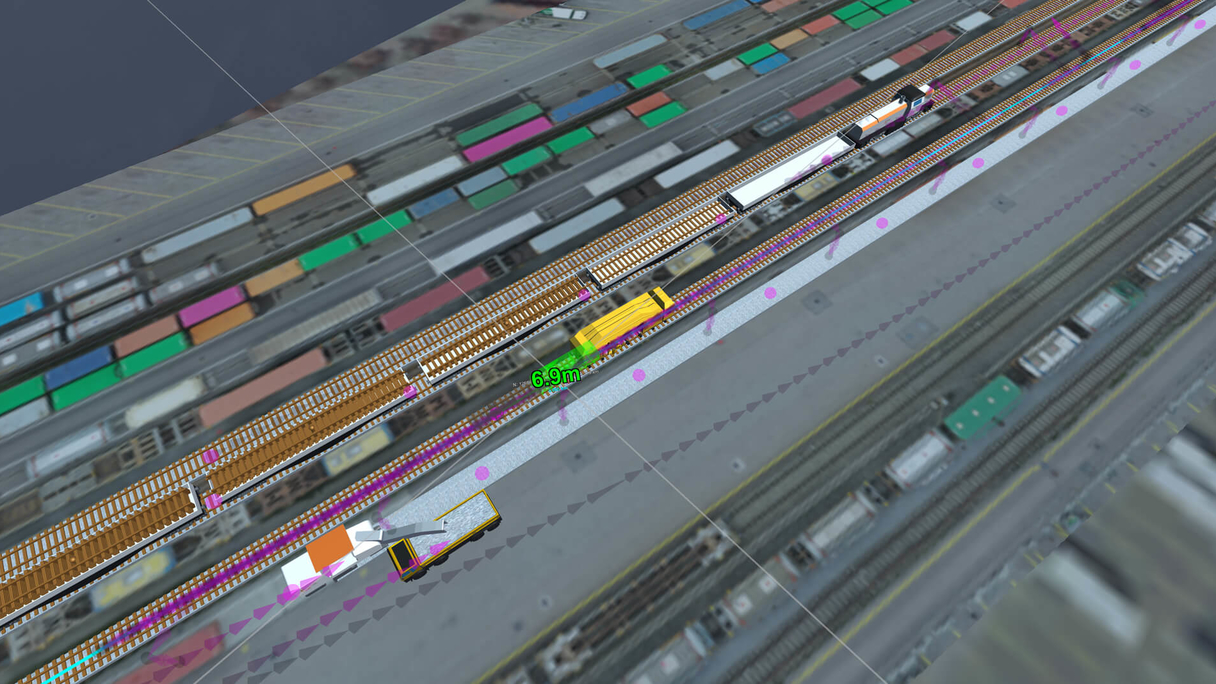

In the software, processes for the removal and assembly of various construction elements are modeled and stored for future use. During design, the individual work steps are then defined and interconnected. The duration of individual processes is either simulated using estimated performance data of the machines and logistics or determined using valid real-world data from previous projects. To simulate the equipment, a 3D model with realistic motion sequences is created respectively, which is stored in a database together with the corresponding performance data.

The individual construction processes are then optimised on the basis of key performance indicators (KPIs), which are defined in advance together with the customer until the perfect construction process has been identified. KPIs can include time, costs or CO2 emissions, for example. Once the "optimal construction process" has been identified, the individual construction processes can be imported into scheduling software such as Tilos via a CSV interface.

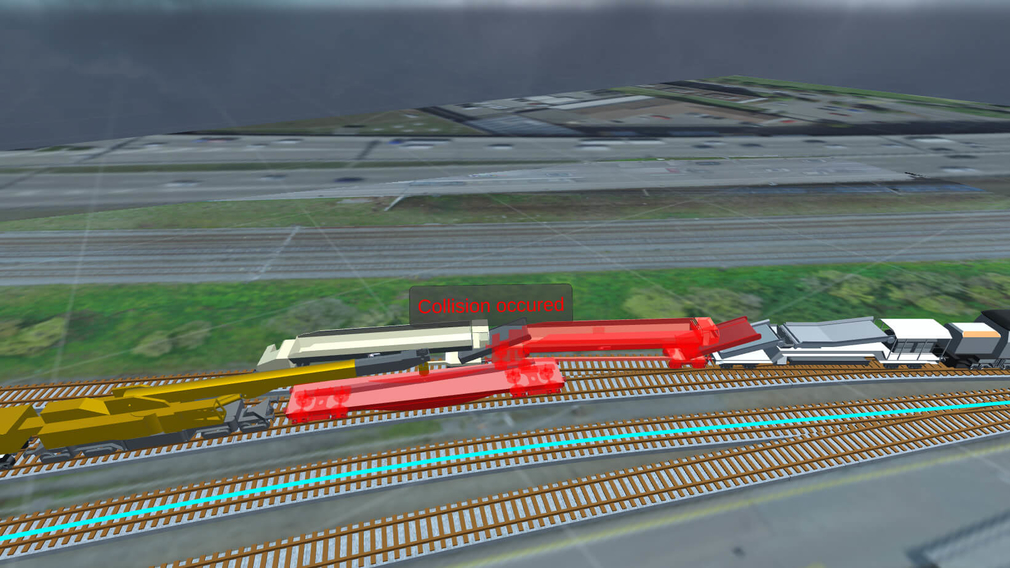

Initial collaborations have shown that this visual way of planning can provide new insights into how to efficiently implement challenging construction sites. Automatic detection of possible collisions, automatic monitoring of all necessary requirements for the machines involved and the ability to quickly plan sequences and detailed processes make planning easier, more cost-effective and more flexible in relation to unpredictable situations. As the simulation can be run from different angles and at different speeds, all parties involved also have an immediate clear understanding of the planning. Through deeper insights into the implementation of individual processes and fewer misunderstandings, construction projects also enormously gain in safety as a result.