Why Deutsche Bahn is adopting the innovative "Rail Partnership Model" for the first time at the new Cottbus plant.

A unique project is currently taking shape in Cottbus. For the first time, Deutsche Bahn, as the client, is applying a completely new alliance model in one of its major infrastructure projects, with the Rhomberg Sersa Rail Group as the premiere partner. The news model brings together the essential project partners in the planning phase rather than later, in the construction phase. "Keep Track" wanted to find out exactly what this entails, how it works, and whether it is indeed successful. For this purpose, representatives of the client and the alliance partners were interviewed.

Mrs. Henning, why did DB choose the innovative partnership model for the NWC?

Hennig The 'New Cottbus Works' is very large project and has a truly ambitious timeline. To manage this successfully, we wanted and needed to take new paths. And it's a great advantage to have all executing companies, and especially the expertise of the participants, on board right from the planning phase. This way, we achieve the goals and even manage to deliver higher quality, better adherence to schedules and cost certainty. The classic issues of overruns and unplanned cost developments at the end of a project are things of the past.

Do the alliance partners see it that way as well?

Henneberger With this project form, it is possible to push forward projects of this magnitude much faster than with conventional contract models. The construction progress alone speaks for itself. The speed in the project is enormous. That's a great success for all involved.

Benker Especially in the co-operation on the construction site, the positive effect of the model is noticeable. The alliance idea is already working very well. Everyone works as smoothly and collaboratively as possible to achieve project success together.

Scheidl From a planner's point of view, the great advantage lies in the continuous processing of the design, approval and execution planning. Normally, the different phases of performance are planned sequentially and sometimes by different offices, now it all comes from one source, flows into each other and thus brings immense time advantages. Just as an example: For the smaller of the two maintenance halls, the construction planners first came together in February 2022 and started construction just four months later. The design and approval planning for the larger hall and the outdoor facilities also started in February 2022, and construction is scheduled to start in January 2024. That says a lot.

What has gone particularly well so far? Where is there still potential?

Hennig The strength of the model has been particularly evident in crises and the difficult global political situation of the recent past. Despite the developments being completely unpredictable, we did not run into delivery or material shortages. This has certainly only been achieved because all partners have aligned their respective strengths and possibilities towards the common goal.

Henneberger We see potential for improvement, as in any large company, in communication and efficiency. With this number of project participants – we are eight alliance partners alone - the organisation and coordination of all those involved is an incredibly large challenge.

Hennig Here we see ourselves as clients also having a responsibility. We have learned that we must allow more time to get to know each other and to ensure clear responsibilities, structures and processes. One must consider that this is a pilot project in which all participants are in a learning process. But the results so far clearly show that we are on the right track together.

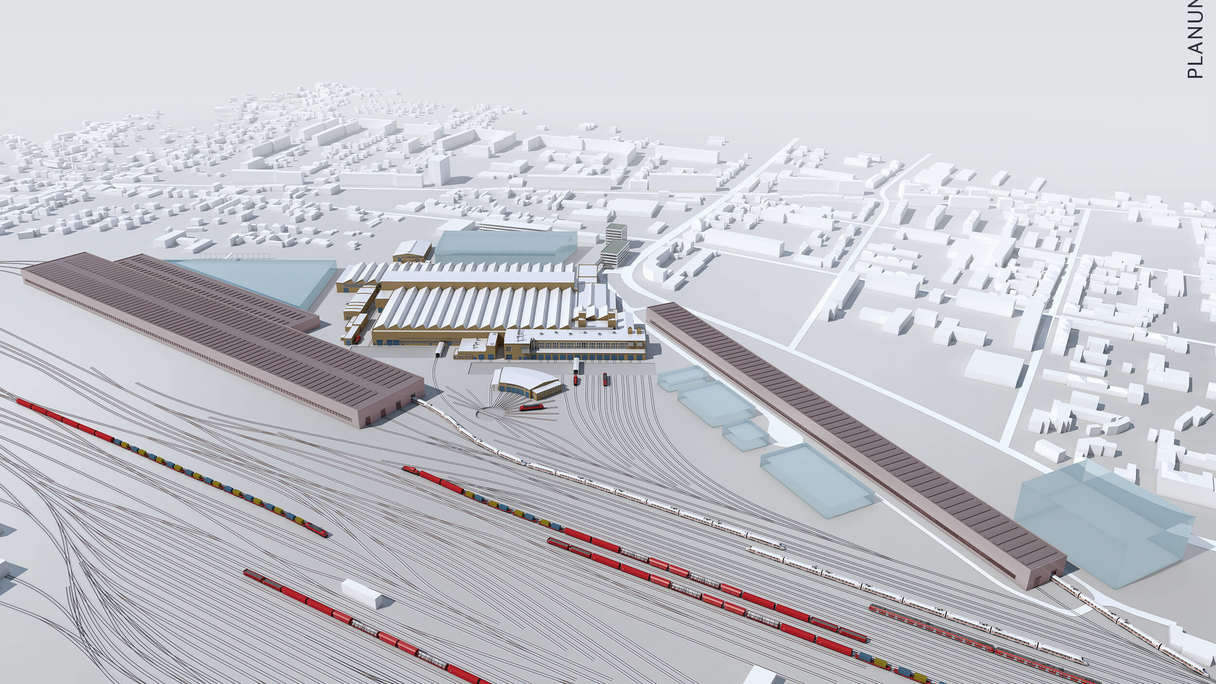

New Cottbus Works

The project "New Cottbus Works" includes the construction of two maintenance halls for electric multiple units for the heavy maintenance level of high-speed traffic. In addition, the conversion of the current compact hall for the revision of hybrid locomotives is planned. The new factory in Cottbus will become the largest maintenance factory in the DB's overall structure. Approximately 1,200 jobs will be created, including about 100 apprenticeships. All are high-quality industrial jobs.

Partnership model

For the first time, Deutsche Bahn, as the client, is using the "Rail Partnership Model" in one of its major infrastructure projects. The idea behind this concept is to implement the extensive and complex major projects quickly, as well as ensuring the project is of high quality, cost-effective and on schedule. This is achieved by bringing together the essential project partners in the planning phase. Through early involvement, all companies can focus their full performance and innovation capabilities on the optimisation, rapid implementation and efficient operation of the construction project.