An interview with Urs Tanner, Project Manager Tunnel Renewal at the Rhaetian Railway, about sustainability and digitalization in tunnel construction.

Mr. Tanner, tunnel construction has evolved significantly in recent years. What role does digitalization play in this?

Digitalization is clearly a driver of innovation in tunnel construction and tunnel renewal. It opens up new possibilities, which also require new forms of collaboration between designers, surveyors, and contractors. But it will not only affect planning—it will also transform execution. For example, a 3D scan can measure to the millimeter how wide a tunnel profile was before and after concreting. This allows us to determine the exact amount of material installed, which can then be invoiced. Of course, procedures, guidelines, and workflows must be defined before execution begins.

I deliberately avoid using the term Building Information Modeling (BIM) here, because in terms of “information” we are not yet there. But the clear goal is comprehensive digital integration of all processes—from initial planning through to maintenance.

We still need to learn how to deal with this. Currently, know-how and personnel resources are not evenly distributed. That will certainly change: if we all move in this direction step by step, we can gain experience and learn from one another. It takes collective will and acceptance. Deviations can then be resolved more quickly, and lessons learned are more easily transferred to future projects. It is crucial that during this learning phase, open and transparent collaboration between clients, designers, and contractors is maintained.

Alongside digitalization, sustainability is another key topic in construction. What measures are you taking in tunnel construction to become more sustainable?

Sustainability starts with the choice of materials. We are currently testing whether we can use concrete with a reduced cement content to lower CO₂ emissions. A promising approach is the use of biochar as an additive, which not only stores CO₂ but also darkens the concrete. This is particularly relevant to us, since we work in UNESCO-protected areas where historical—darker—tunnel appearances must be preserved. Another exciting project is the use of waste products from desalination plants as a concrete additive, helping to further reduce resource consumption.

Even today, we are managing to combine tunnel renewal, sustainability, and environmental protection. A good example is the renewal of the two Brail tunnels in the Engadin: during the approval procedure for Brail Tunnel I, the Federal Office for the Environment feared that construction could severely disrupt the breeding behavior of local eagle owls. Luckily, we were already working on Brail Tunnel II at the same time. Together with the environmental monitoring team and an ornithologist from the Swiss Ornithological Institute in Sempach, we used the opportunity to measure noise and vibrations in the surrounding area over an extended period. In early summer 2024, we were actually informed that, after several years of absence, a pair of owls had returned to the area and started breeding right next to our project. The pair successfully raised two chicks, which left the nest healthy and strong - despite blasting and vibrations.

Are there sustainable developments in the construction process itself?

Yes, with our “Standard Tunnel Construction Method” and the use of prefabricated elements, we have essentially adapted modular construction for tunnel renewal, including all its benefits for resource efficiency and emission reduction. We reduce material use, minimize construction waste, and significantly shorten construction times. This lowers energy consumption and reduces disruptions to railway operations. In addition, we are testing modern construction machinery equipped with particle filters or powered electrically to cut emissions on site.

Is this serial approach to RhB tunnel renewal also interesting for other railway companies?

Yes, the concept is in principle transferable. In Germany, a pilot project has already been launched based on our experience. However, regulatory hurdles remain, especially regarding component approval. This shows that innovative approaches bring not only technical but also administrative challenges. We very much welcome it when other railway companies adopt and further develop our concept, because shared experience would benefit the entire industry.

Finally, what developments do you see for the future of tunnel construction?

The combination of digitalization and sustainability will fundamentally transform tunnel construction. Automated processes, new materials, and closer cooperation between clients, planners, and contractors will be decisive. Alliance models, where all stakeholders sit at one table and share responsibility, may become increasingly important. Technological advances will continue to challenge us, but they also offer tremendous opportunities. I’m very curious to see where this journey will take us!

About the Interviewee

Since 2012, Urs Tanner has been “Project Manager Tunnel” at the Rhaetian Railway, responsible for introducing and developing the Standard Tunnel Construction Method and its implementation in RhB projects. Trained as a civil engineering draftsman and construction supervisor, he previously gained tunneling experience working at a surveying office, a construction chemicals supplier, and a plastic pipe manufacturer. Born in Graubünden, he has contributed to projects such as the Promontogno bypass tunnel and the NEAT “Sedrun access shaft,” and later accompanied tunnel projects in Graubünden and Valais.

Factbox: The “Standard Tunnel Construction Method”

Most RhB tunnels were built in the early 20th century. To ensure they continue to meet the requirements of modern railway operations, RhB will need to renew around half of its 115 tunnels over the coming decades. For this purpose, the company has developed a new standardized repair method: the Standard Tunnel Construction Method. It guarantees regulated workflows, lower costs compared to traditional methods, and enables renewal during ongoing operations. Moreover, it extends tunnel lifespans from today’s 30–50 years to 70–100 years.

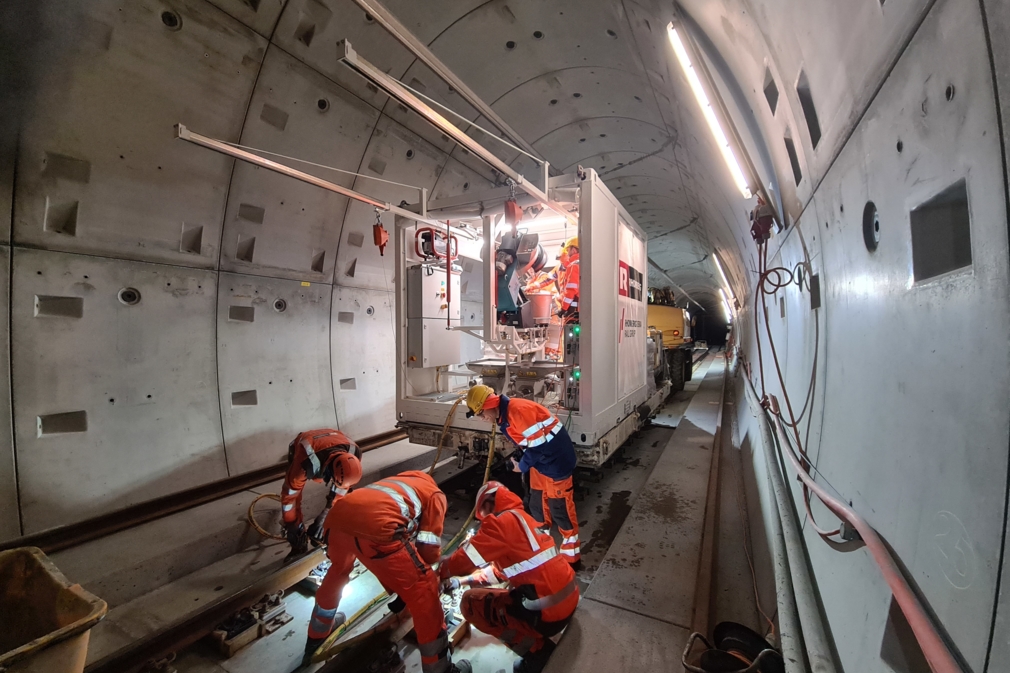

In this new method, tunnel walls are completely replaced rather than merely repaired. This involves lowering the track, enlarging the tunnel cross-section, installing new drainage, inserting prefabricated concrete wall elements as the inner lining, and rebuilding the portals.

The Standard Tunnel Construction Method was first applied in 2014 during the renewal of the 108-year-old, 334-meter-long Glatscheras Tunnel near Bergün—with Rhomberg Sersa Rail Group as a partner! The track was lowered by 52 cm, the tunnel cross-section was enlarged using drill-and-blast excavation, and prefabricated concrete elements were installed from freight wagons. With this project, RhB took on a pioneering role and sparked the interest of other railway companies.

In 2019, during work on the Bergünerstein Tunnel, RhB and RSRG for the first time implemented a slab track in such a project.

About the Rhaetian Railway

“With around 1,800 employees, we offer 15.5 million passengers per year a unique travel experience through Graubünden.

Our 385-kilometer-long network is impressive in numbers: one-third lies above 1,500 meters above sea level; one-third belongs to the UNESCO World Heritage RhB; and one-fifth runs on or through engineering structures.

With our regional and freight trains, as well as the Vereina car shuttle, we ensure reliable transport chains throughout the canton of Graubünden. With our panoramic trains Bernina Express and Glacier Express, and with the UNESCO World Heritage ‘Rhaetian Railway in the Albula/Bernina Landscape,’ we operate brands of worldwide renown—brands we cultivate and position together with our tourism partners.

We run a customer-friendly railway, operating safely, cleanly, and punctually every single day. We move Graubünden and inspire customers from all over the world. With efficient operations, new and modern rolling stock, expanded services, and captivating products, we aim to further enhance the Rhaetian Railway experience: powerful, modern, and with an unmistakable Graubünden character.

We act sustainably: strengthening century-old bridges and tunnels for the future, improving energy efficiency, and relying on renewable hydropower. With the new Albula Tunnel, we are right in the middle of a once-in-a-century project.

All of this is only possible thanks to the great commitment of our 1,800 employees. Together with strong partners in tourism and business, and with the strong support of our owners and clients—the Swiss Confederation and the canton—we proudly serve ‘their’ railway.”