Number 1 in North America

A rail milling train in action.

A powerful LINSINGER SF02T-FS LB rail milling train has been in use for Rhomberg Sersa in Toronto since January 2021.

It is the first rail maintenance machine in North America that can identify cracks on the rail surface: the LINSINGER SF02T-FS LB rail milling train. The train is fitted with the latest profile measurement technology to determine transverse profile, longitudinal profile and wear. In addition, it uses a Sperry eddy current system for crack detection and crack depth determination. This eddy current system is already being used successfully in Ireland and Great Britain and is currently also being tested for use in North America.

The milling train has the latest diesel-electric exhaust system to meet the strictest North American emission standards. The milling technology efficiently eliminates rail damage and restores rail profiles without generating sparks or dust. In addition, the machine can be used for longer periods of time without having to refuel or empty the chip bunker. The train is equipped with a point add-on function that enables the machine to process points and crossings in addition to the main track. Thanks to the unique low bed design, the train not only fits into the smallest clearance gauges, but is also suitable for use on freight railways and “Light Rail Transit” systems.

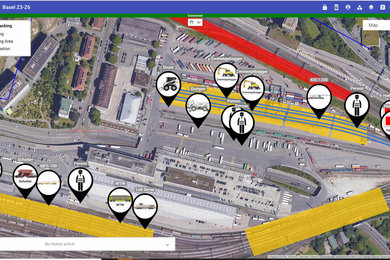

Rhomberg Sersa won a multi-year contract with the Toronto Transit Commission metro and was busy with rail milling in Toronto until early summer 2021.The machine was then used at Metrolinx, which manages the public transport system for the entire Toronto area.