The Semmering Base Tunnel project relies on state-of-theart working methods.

In this complex large-scale project, RSRG – together with joint venture partner PORR AG – is responsible for the entire technical equipment of the tunnel, including execution and installation planning, implementation, and final as-built documentation. The team is using Building Information Modelling (BIM) and Lean Management to enhance efficiency, schedule and cost reliability, as well as execution quality.

Building Information Modelling (BIM) allows for continuous digital modelling and coordination across all trades. All planning disciplines benefit from detailed 3D modelling, which helps detect clashes at an early stage and significantly reduces on-site changes. BIM also fosters transparent collaboration among all parties involved. The entire planning process is consolidated in a lean board, allowing potential challenges to be identified and addressed early.

A central element in this process is the overall BIM coordination which, in this project, RSRG is implementing for the first time together with its subsidiary EDS. This ensures interdisciplinary model integration, information management, and high-quality models and planning outputs.

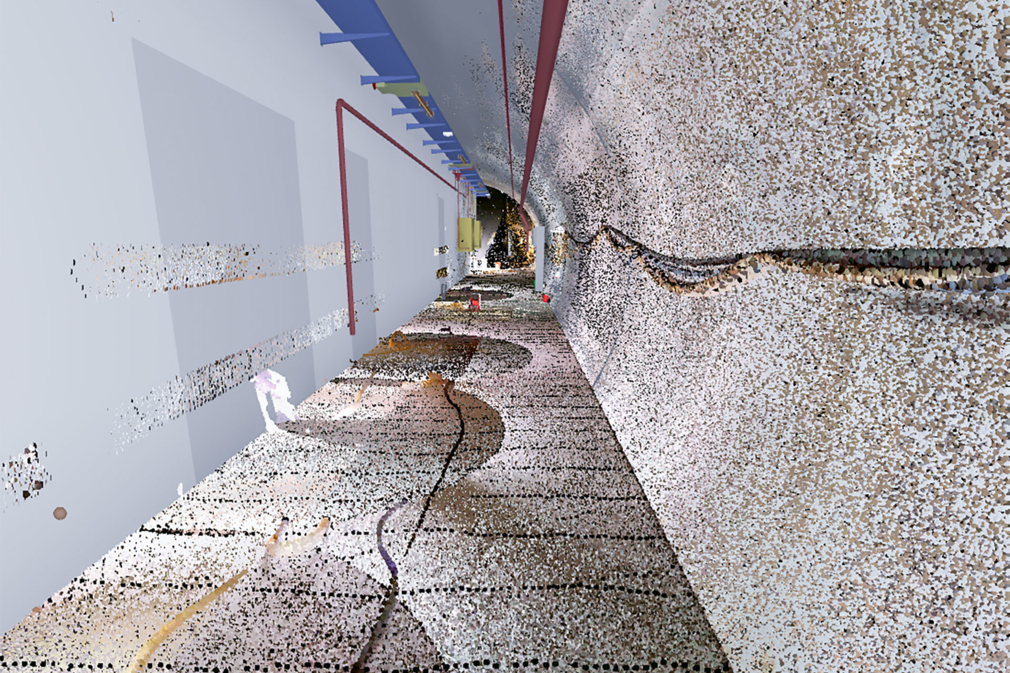

The actual site conditions are recorded via laser scanning and integrated into the BIM model as point clouds. This enables early detection of discrepancies between the design and the construction site, helping to reduce errors and rework. Coordination across the different disciplines is more seamless, resulting in a smoother process on site.

Construction teams benefit directly from well-structured trade-specific models. These clearly show the current planning status (the “target condition”) on site. Everyone is aligned and can quickly get their bearings. Unclear points? They’re addressed directly within the model – with no lengthy backand-forth or rounds of clarification.

This approach has proven particularly effective in defect management: QR codes placed inside the tunnel link directly to the current model. Defects can be recorded directly at the correct component in the model – clearly, transparently, and for everyone to see.

The logistics process has also been newly designed – lean, practical and well-structured. With lean methods, digital tracking, and efficient storage space management, all work steps, deliveries and removals can be reliably documented and monitored. This helps everyone involved stay on top of the construction process and material flows therefore improving coordination and ensuring smoother operations on site.

In addition to model usage and on-site coordination, commissioning and daily site reporting for the Semmering Base Tunnel are also handled digitally via a central system. This makes all processes, inspections and progress transparent at any time, saving time and significantly simplifying site management.

Semmering Base Tunnel

The SBT is one of Europe’s most important infrastructure projects and a key rail link between Lower Austria and Styria. At 27.3 kilometres in length, the tunnel will significantly reduce journey times on this vital route and increase capacity for both passenger and freight traffic.