Thanks to RSRG expertise: increased performance for a vital Alpine transit corridor.

After 115 years in operation, the Tauern Tunnel has been future-proofed through extensive refurbishment works. Rhomberg Sersa Rail Group was responsible for both the railway systems installation and signal technology – once again demonstrating its expertise in complex tunnel projects.

The Tauern line between Salzburg and Villach is one of Austria’s most important Alpine transit routes and a key axis for north–south rail traffic. The required refurbishment works began with the first construction phase between November 2024 and July 2025.

RSRG successfully secured the contract for both electrical engineering disciplines. Teams from two locations combined their expertise to deliver a one-stop solution for the client. As part of the modernisation of the historic Tauern Tunnel, RSRG’s Tunnel Equipment team in Austria – together with a partner – was responsible for the second-largest work package of the entire project.

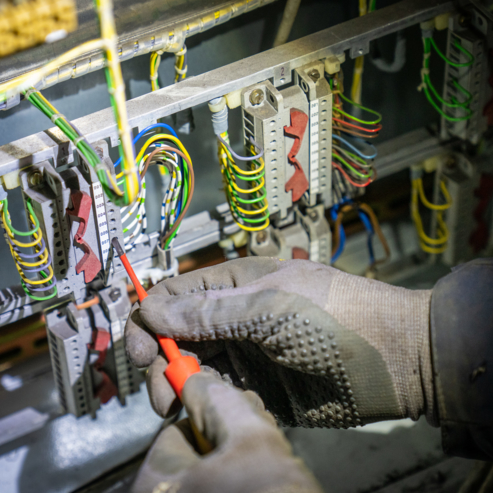

Work began immediately after the contract was awarded. The Control and Safety Technology (LS) team dismantled components including intermittent automatic train control (PZB), speed monitoring systems, light signals (including signal boxes) and axle counters.

The tunnel equipment team began by removing all components from the tunnel cross-section to quickly provide a clear worksite for the structural refurbishment contractor.

Throughout the entire structural phase, RSRG maintained ongoing dialogue with the client (ÖBB-Infrastruktur AG) and all other contractors to ensure technical accuracy, regulatory compliance, and smooth coordination. This proactive approach helped avoid any delays within the tight schedule.

In parallel with the construction works, the team installed handrails along both tunnel walls and began mounting niche components for the telematics and 50 Hz systems.

In April this year, the main rail-based works began – including the machine-assisted pulling of approximately 200 kilometres of cable, with daily progress of up to 10 km. These activities also included radio installations and final system testing.

The LS team also installed and commissioned modern PZB magnets and axle counters.

For this project, RSRG’s Tunnel Equipment Austria team and its partner were responsible not only for their core expertise – the 50 Hz installation – but also for the full telematics infrastructure, installation of mechanical systems and air flow monitoring stations. The team also handled all structural fire protection measures and installed specially developed tunnel doors designed for operation under extreme conditions.

The greatest challenge, as is often the case, was coordinating the various trades – particularly because only one of the two tracks could remain in operation. However, RSRG’s teams rose to the occasion. One of the key success factors was the collaborative, solution-oriented partnership between the contractors and the client.