RSRG’s slab track system IVES shows its strengths where track possession times are getting ever shorter.

The growing success of rail as a sustainable mode of transport is leading to increasingly dense train schedules. At the same time, much of Europe’s rail infrastructure is ageing. Thankfully, there’s IVES.

While tunnels typically have a service life of around 100 years, track infrastructure – depending on design speed, axle load and superstructure type – generally lasts between 40 and 60 years. Additionally, many older tunnels no longer meet the clearance requirements of modern electric trains. In short, large parts of the global rail infrastructure – including tunnels – are due for refurbishment and modernisation, especially as many operators are aiming to increase train capacity even further.

In the UK, Ireland, Germany and Australia alone – all key markets for RSRG – there are around 1,000 kilometres of railway tunnels. At a conservative annual refurbishment rate of three percent, this would mean refurbishing some 32 kilometres of tunnel each year. Deutsche Bahn, for example, is tackling this enormous challenge through so-called corridor projects, where entire route sections are comprehensively renewed in very short timeframes. The aim is to improve the network’s infrastructure “grade” (comparable to a school rating) from “barely sufficient” to “good” or “very good”.

Fast, precise, and durable

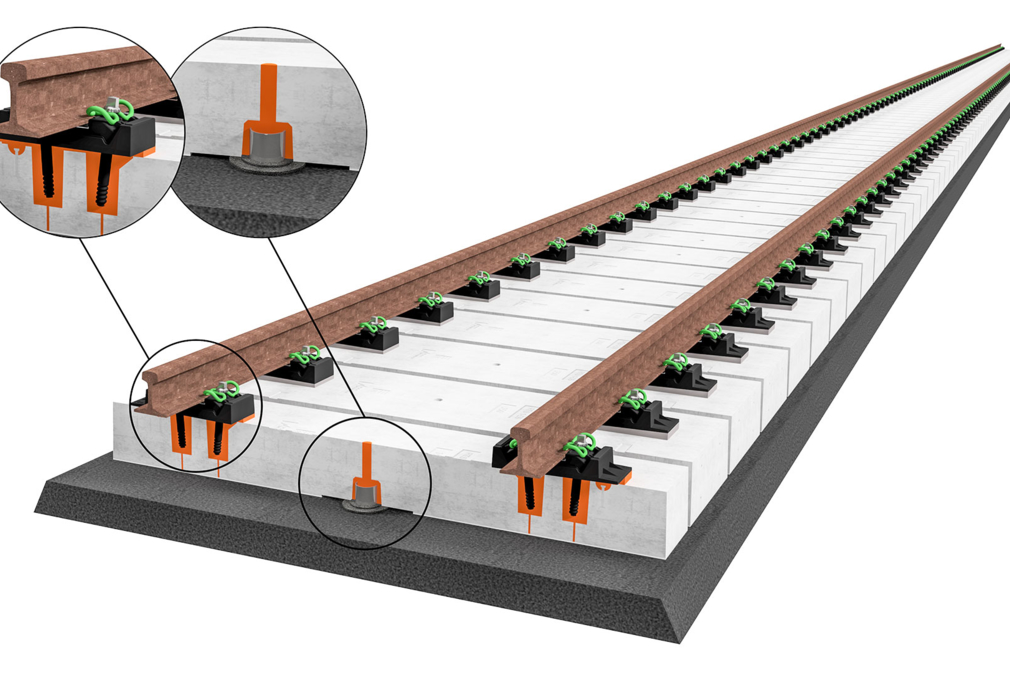

This is where the IVES slab track system from Rhomberg Sersa Rail Group comes in. Developed thanks to decades of experience with all common slab track systems, IVES is designed for rapid installation, high precision, and low maintenance. It truly shines in tunnel applications – especially single-bore tunnels.

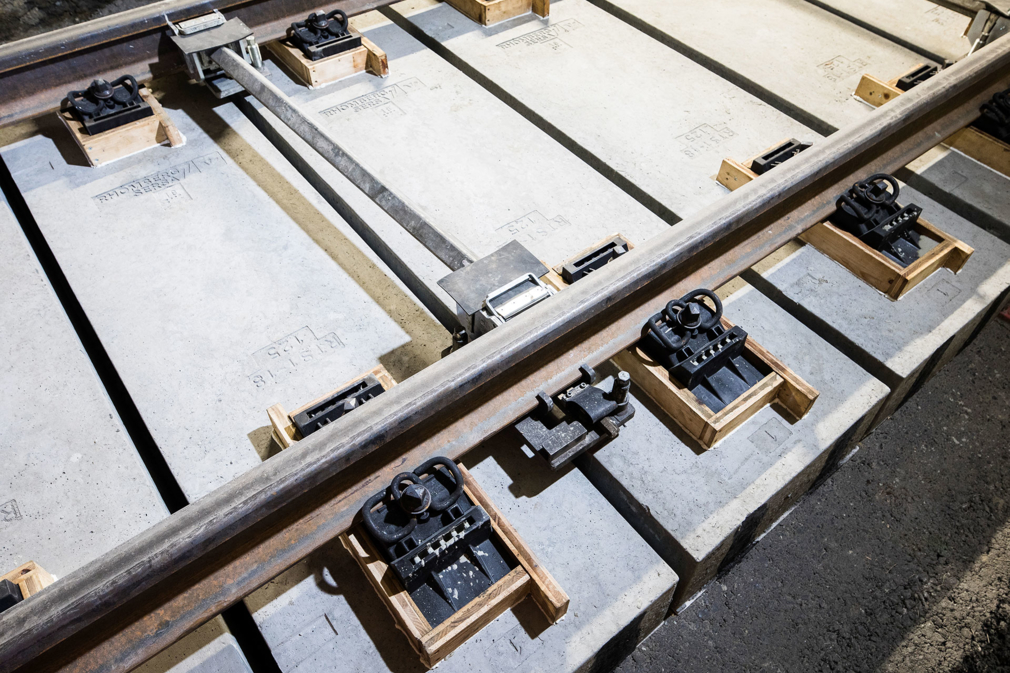

After the prefabricated IVES concrete slabs are laid, they form a flat surface immediately accessible to rubber-tyred construction vehicles. The patented direct fastening system Vossloh DFF 300 RS – developed jointly by RSRG and Vossloh – enables top-down installation using fast-curing grout (either cement- or epoxy-based). The RhoFAS system for track alignment even allows the use of lightweight rail-bound vehicles with axle loads under 1.5 tonnes during the grouting process.

Thanks to these features, construction logistics are not limited to a single tunnel portal – materials, equipment and personnel can be brought in from multiple access points. While IVES is suitable for use on open track as well as in tunnels, its advantages are particularly evident in tunnel modernisation or new-build projects.